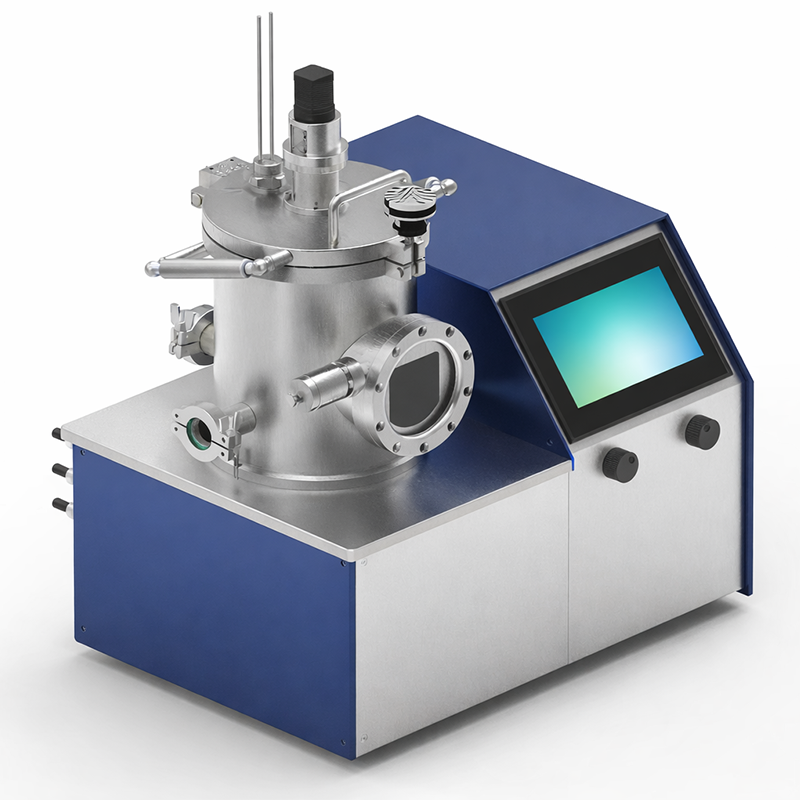

Three-Target Magnetron Sputtering System Description

The three-target magnetron sputtering system is designed for flexible thin film deposition and co-sputtering applications. It is equipped with three independent magnetron sputtering cathodes, allowing sequential sputtering, co-sputtering, or multilayer film deposition within a single process cycle.

Each magnetron target can be configured with DC or RF power supplies according to the material properties, making the system suitable for metallic, alloy, semiconductor, ceramic, and dielectric coatings. Independent power control enables precise adjustment of deposition rates and film composition.

The vacuum chamber is manufactured from high-quality stainless steel and features multiple ports for magnetron heads, gas inlets, vacuum pumping, and observation windows. Uniform film thickness is achieved through optimized target geometry and optional substrate rotation.

This three-target magnetron sputtering system is widely used in research and development, functional thin films, optical coatings, electronic materials, and advanced material studies, where high repeatability, process flexibility, and material compatibility are required.

Technical Parameters:

| No. | Parameter | Specification |

| 1 | Model | KS-PVD-MS450 |

| 2 | System Type | High vacuum multi-cathode magnetron sputtering system |

| 3 | Loading Method | Manual substrate loading |

| 4 | Base Pressure (Ultimate Vacuum) | ≤ 5 × 10⁻⁷ mbar |

| 5 | Working Pressure Range | 1 – 5 mTorr |

| 6 | Pressure Control | Automatic pressure control |

| 7 | Vacuum Measurement | Full range vacuum gauges |

| 8 | Turbo Molecular Pump Speed | 1200 L/s |

| 9 | Dry Backing Pump Speed | 4 L/s (≈14.4 m³/h) |

| 10 | Number of Magnetron Cathodes | 3 pcs |

| 11 | Cathode Mounting | Top-mounted |

| 12 | Target Size | 2 inch diameter |

| 13 | Target Cooling | Direct water cooling |

| 14 | Source Shutters | One shutter for each cathode |

| 15 | Cathode–Substrate Distance | Adjustable, 5 – 10 cm |

| 16 | DC Power Supplies | 2 units |

| 17 | DC Power Range | 0 – 600 W |

| 18 | RF Power Supply | 1 unit |

| 19 | RF Power Specification | 13.56 MHz, ≥ 600 W |

| 20 | Compatible Deposition Materials | Ti / Pt / Au, AuGe / Ni / Au |

| 21 | Process Gas | Argon (Ar), 99.999% purity |

| 22 | Gas Flow Control | Mass Flow Controller (MFC) |

| 23 | Reactive Gases | N₂ / O₂ (optional) |

| 24 | Thickness Monitoring | In-situ Quartz Crystal Monitor (QCM) |

| 25 | Quartz Crystals | 2 pcs |

| 26 | Substrate Size | Up to 3 inch wafers |

| 27 | Substrate Heating Temperature | Up to 500 °C |

| 28 | Substrate Rotation Speed | 0 – 20 rpm |

| 29 | Film Thickness Uniformity | ≤ 3% within effective 3-inch area |

| 30 | Control System | PC / PLC control |

| 31 | Software Platform | Compatible with Windows 10 |

| 32 | Power Requirement | 220 – 240 VAC, 50 Hz |