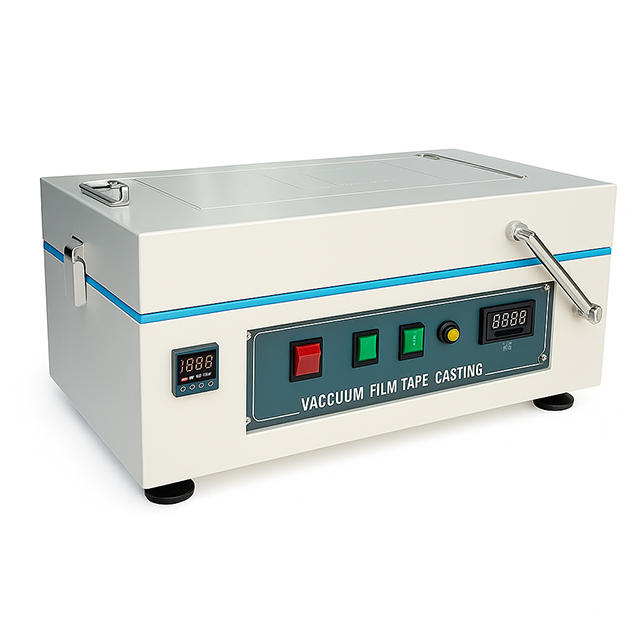

Product Description:

KS-DC-DS300 double-sided dip

coating experimental coater is an experimental coater that combines dip coating

and wire bar metering. This machine adopts the traditional dipping coating

method to coat both sides of the substrate at the same time, uses wire rods to

measure the coating liquid on the surface of the substrate respectively, and

winds up after passing through the drying box. The equipment has simple

structure, convenient operation, high production efficiency, and wide

application range. It can be applied to lithium-ion batteries, graphene films,

ceramic films, high-end tapes and various functional film industries.

Product Features:

1. Dip coating:

double-sided coating can be achieved at the same time, and

surface coating requirements for special substrates can be realized.

The material box is automatically circulated to ensure the height of the

working liquid level.

Modular structure, which can quickly remove/install the material box

2. Measurement Wire rod:

standard wire rod, parameters can be customized according to customer

requirements.

Thickness measurement can be performed on both sides of the substrate at the

same time. Modular structure, which can quickly remove/ install

wire rod . The temperature in the box is uniform , the air volume can

be adjusted, so as to adjust the number of air changes . The closed-loop

tension control of the substrate, the tape running is stable, and the

low-tension tape running can be realized. The rewinding and deviation correction

function is configured, which is easy to operate and has high deviation

correction accuracy. PLC control, HMI operation, convenient and easy

Use the optional solvent recovery treatment device.

Technical Parameters:

| Product Model | KS-DC-DS300 double slide dip coater |

| Power supply | voltage single-phase AC220V±10% (customizable 110VAC), frequency 50Hz/60Hz, power 6KW |

| Air source | 0.5-0.8MPa compressed air |

| Operating environment | recommended ambient temperature 25±3℃, humidity 30 ~90RH, no vibration and electromagnetic interference |

| Coating method | dipping coating |

| Coating type | continuous coating |

| Guide roller width | 300mm |

| Coating width | Max. 280mm |

| Applicable substrate | copper Foil, aluminum foil, PET film, PP film, PE film, etc. |

| Coating accuracy | ±3μm (related to slurry characteristics) |

| Coating thickness wire bar | 3-50μm (reference value), determined by slurry and substrate And coating speed decision |

| Wire rod specification diameter | 10mm, length 400mm, parameter specifications are selected according to customer requirements |

| Mechanical speed | Max.5000mm/min |

| Tension control | 5-40N |

| Winding accuracy | ±0.5 mm |

| Rewinding and unwinding roll diameter | Max. 300mm |

| Hot air drying oven Method | Electric heating, hot air direct exhaust |

| Air volume | Max. 9.5/2800 (CMM/RPM), air valve adjustment |

| Temperature | Max.150℃, can be set |

| Power | 4KW |

| Length | 800mm |