| Model | KS-PVD-ARC650 |

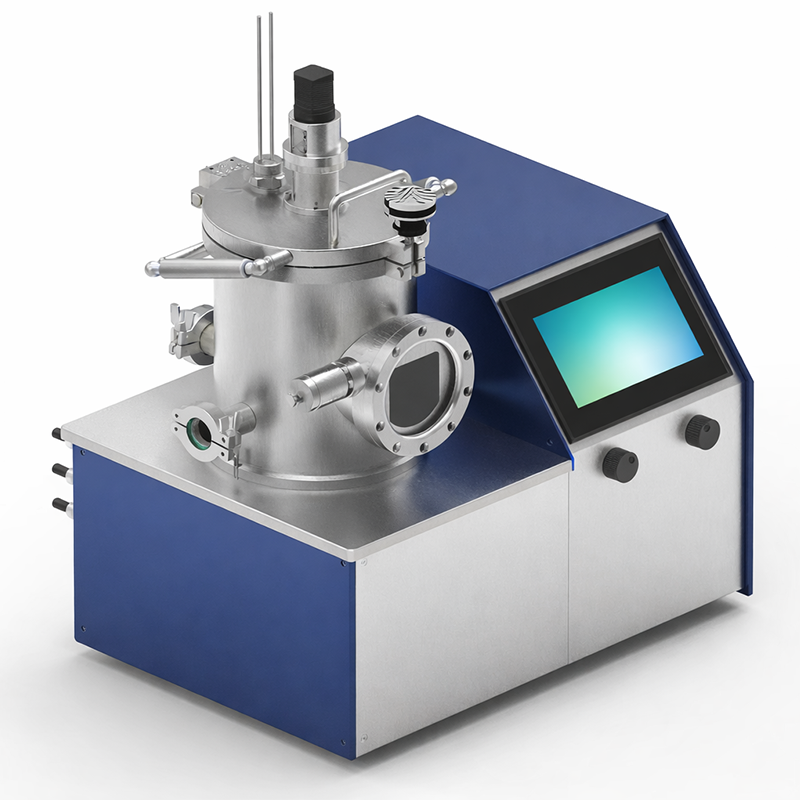

| System Type | Hybrid PVD Arc Deposition & Magnetron Sputtering Coating System |

| Vacuum Chamber Structure | Vertical, single chamber, stainless steel with double-layer water cooling jacket |

| Vacuum Chamber Inner Size | Diameter 650 mm × Height 650 mm |

| Chamber Material | Stainless Steel 304, inner surface polished |

| Observation Port | Optical observation window on chamber door |

| Ultimate Vacuum Pressure | ≤ 1.0 × 10⁻⁴ Pa |

| Pump-down Time | ≤ 30 min from atmosphere to 5.0 × 10⁻³ Pa |

| Working Heating Temperature | ≤ 500 °C (≥ 450 °C required) |

| Temperature Control Accuracy | ± 5 °C |

| Heating Method | Resistance heaters installed on chamber wall and center |

| Arc Evaporation Sources | 3 sets cathodic arc sources, DC working mode |

| Arc Power Supply | 10 kW arc power supply for each arc source |

| TiN Deposition Rate (Arc Mode) | ≥ 5 μm/h |

| Magnetron Sputtering Source | MF planar magnetron sputtering cathode, water cooled |

| Magnetron Deposition Rate (TiN) | ≥ 2 μm/h |

| Ion Source | Low-energy ion source, 10 kW |

| Substrate Rotation | Planetary rotation system, dual planetary structure |

| Number of Planets | ≥ 6 planetary holders |

| Max. Substrate Load | ≥ 120 kg |

| Film Thickness Uniformity | ≤ 5 % |

| Average Noise Level | ≤ 75 dBA |

| Mean Time Between Failures (MTBF) | ≥ 1000 h |

| Vacuum Pump System | Mechanical pump + dry screw pump + turbo molecular pump |

| Gas Supply System | Mass Flow Controllers (MFC), automatic gas mixing |

| Applicable Gases | Ar, N₂, O₂, C₂H₂, etc. |

| Control System | PLC control system with 15-inch touch screen |

| Installed Power | About 105 kW |

| Average Power Consumption | About 50 kWh |

| Cooling System | Closed-loop water chiller system |

| Compressed Air Requirement | 0.5 – 0.6 MPa |

| Machine Dimensions (L×W×H) | Approx. 2.3 × 1.6 × 1.95 m |

| Machine Weight | Approx. 1550 kg |

| Warranty | 12 months |