The

KS-EBV-600 is a high-vacuum electron beam evaporation system designed for

precision thin film deposition. It is capable of depositing a wide variety of

materials, including metals, oxides, semiconductors, magnetic layers, and

compound or doped films. This system is ideal for research institutions and

advanced material laboratories requiring high purity and multi-layer coatings.

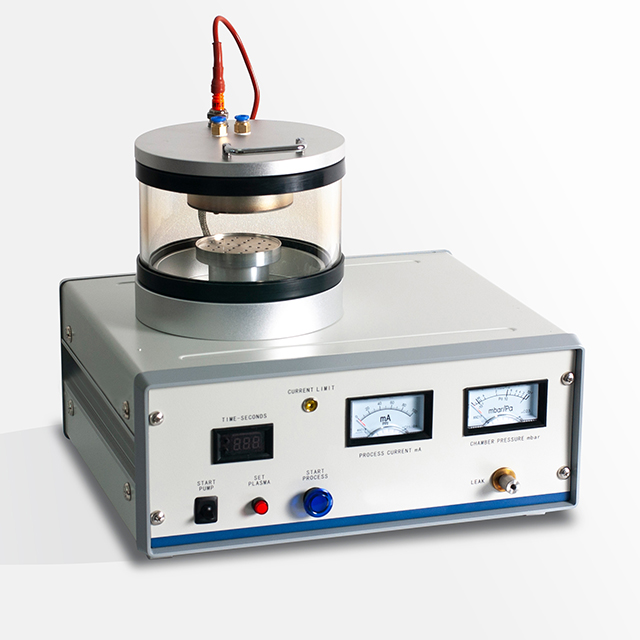

The

system features a robust stainless-steel vacuum chamber (Ø650 × 600 mm)

equipped with a single-station, motorized rotating substrate holder supporting

up to 200 × 200 mm wafers. A powerful 8 kW electron beam gun with a 270° beam

deflection angle is integrated, utilizing a four-hole oxygen-free copper

crucible with motorized position switching to allow for multilayer or alloy

film deposition without breaking vacuum.

Vacuum

performance is ensured by a high-capacity 1400 L/s turbomolecular pump backed

by a mechanical pump, achieving an ultimate vacuum of 7×10⁻⁵ Pa after baking. The

system supports automatic pumping sequences, real-time vacuum monitoring, and

comprehensive interlock protections.

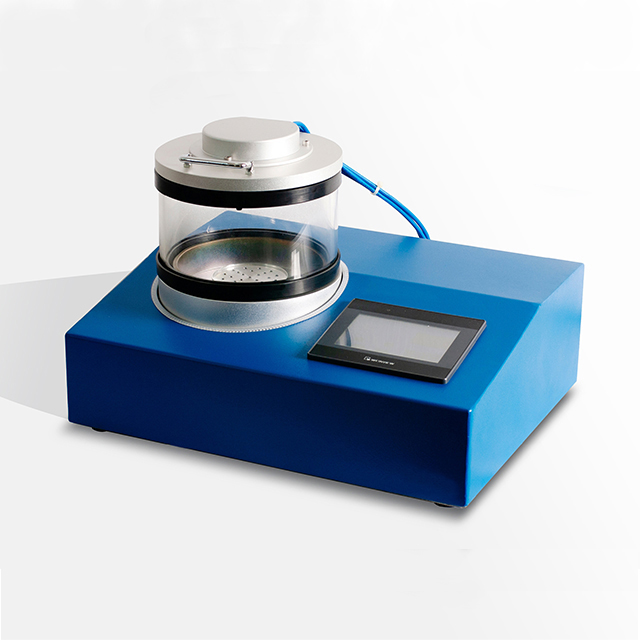

Control

is provided via a user-friendly LG PLC with a 10-inch touch screen, enabling

full automation of vacuum control, substrate rotation, and source switching.

Deposition rate and film thickness are monitored using an INFICON 160

dual-channel thickness monitor. Optional features include water-cooled

substrate holders, organic evaporation sources (up to 650°C), and programmable

beam scanning.

The

KS-EBV-600 is delivered as a complete turnkey system, including the control

cabinet, vacuum chamber, and all necessary electronics and peripherals. It is

suitable for advanced R&D in optics, electronics, nanotechnology, and

material science.

Technical Parameters:

| Model | KS-EBV-600 |

| Ultimate Vacuum | 7×10⁻⁵ Pa (after baking) |

| Working Background Vacuum | ≤5×10⁻⁴ Pa within 30 min |

| Chamber Size | Ø650 mm × 600 mm |

| Chamber Material | SUS304 stainless steel with internal polishing |

| Sample Holder | Single station, electric rotation 0–30 rpm |

| Sample Size | 200 mm × 200 mm |

| Electron Gun Power | 8 kW |

| Beam Deflection Angle | 270° |

| Crucible Type | Four-hole water-cooled oxygen-free copper |

| Crucible Volume | 10 ml per hole, motorized switching |

| Source-to-Substrate Distance | 350 ± 20 mm |

| Main Valve | CF200 pneumatic gate valve |

| Observation Window | CF100 with anti-contamination baffle |

| Pumps | 1400 L/s turbomolecular pump + backing pump |

| Control System | LG PLC + 10" touchscreen (Kunlun Tongtai) |

| Deposition Monitoring | INFICON 160 dual-channel thickness monitor |

| Vacuum Gauge | ZDF-5527 digital combined gauge |

| Power Supply for Metal Evaporation | 0–200 A |

| Organic Evaporation Source | Heating up to 650°C |

| Electron Gun Control | Programmable with high-voltage supply & scanning |

| Cooling | Water cooling with 3 hydraulic bellows lines |

| Gas Supply | Supports N₂, Ar, O₂ with φ6 compression fitting |

| Cleanliness Requirement | Better than Class 100,000 |

| Power Supply | 380V 3-phase + 220V single-phase (12 kW total) |

| Warranty | 1 year after acceptance |