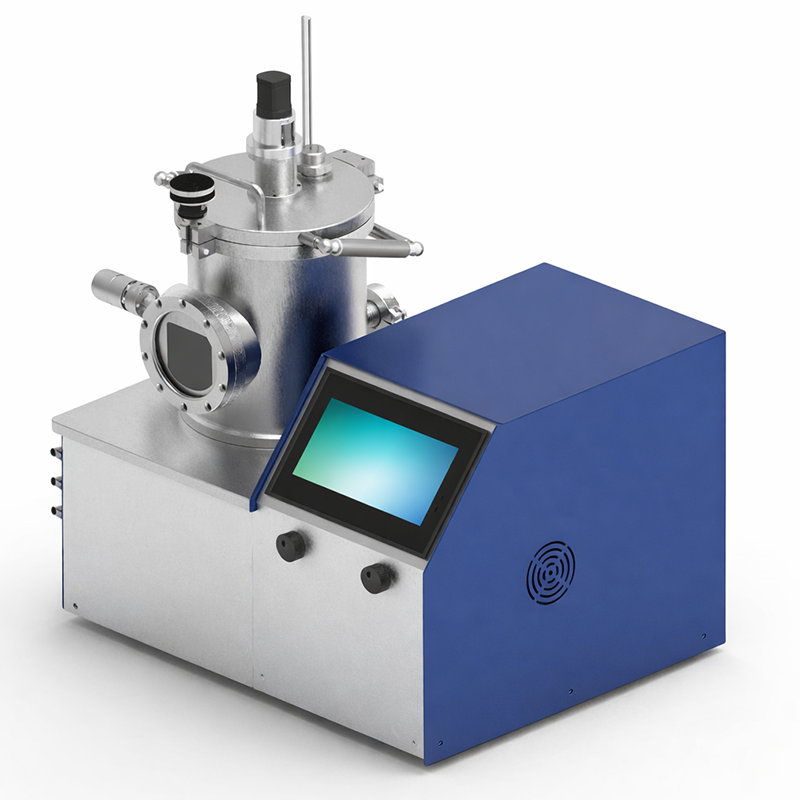

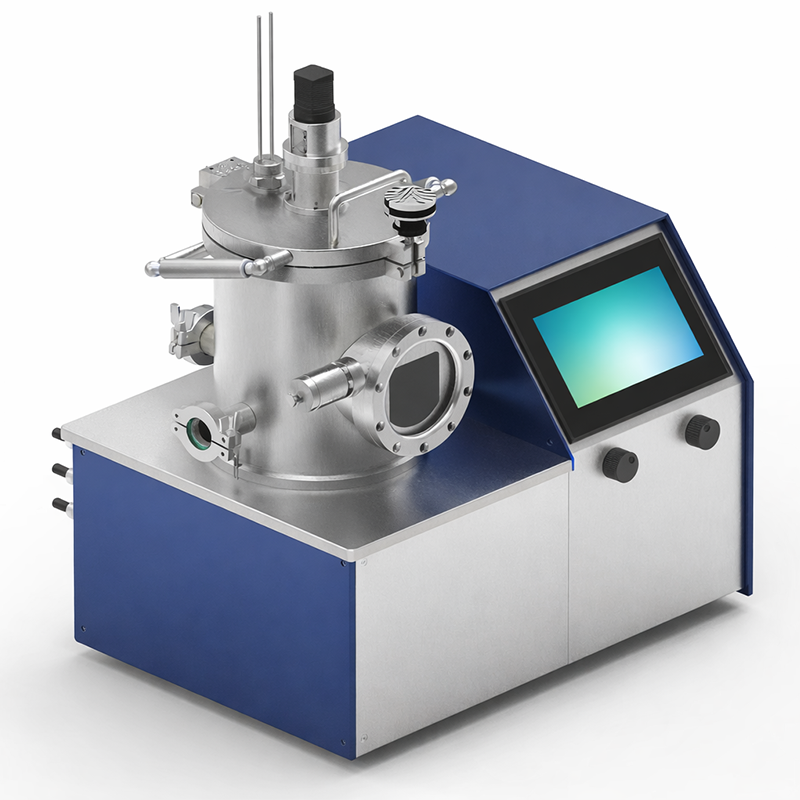

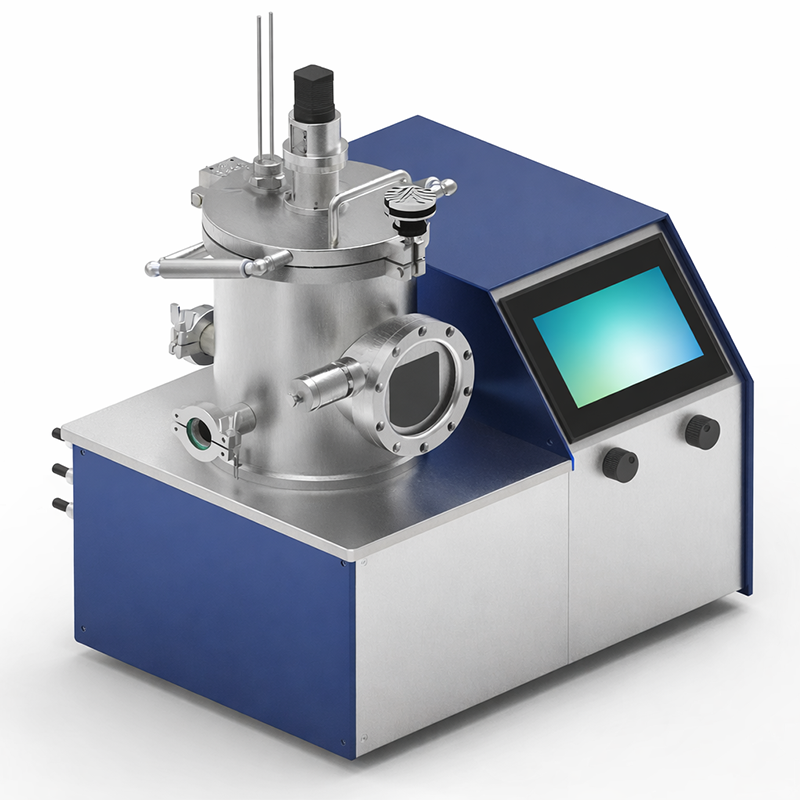

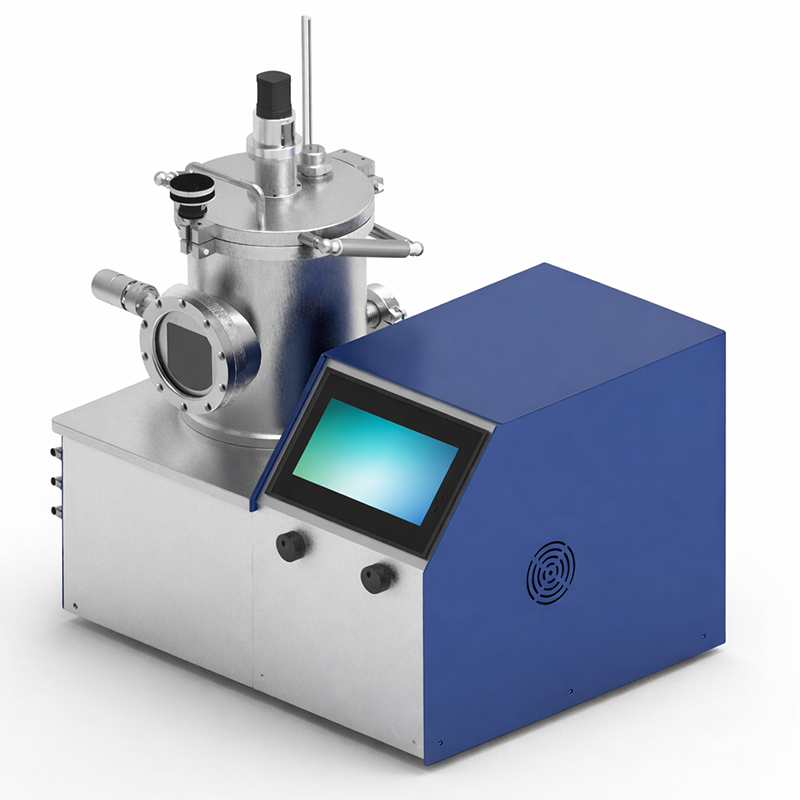

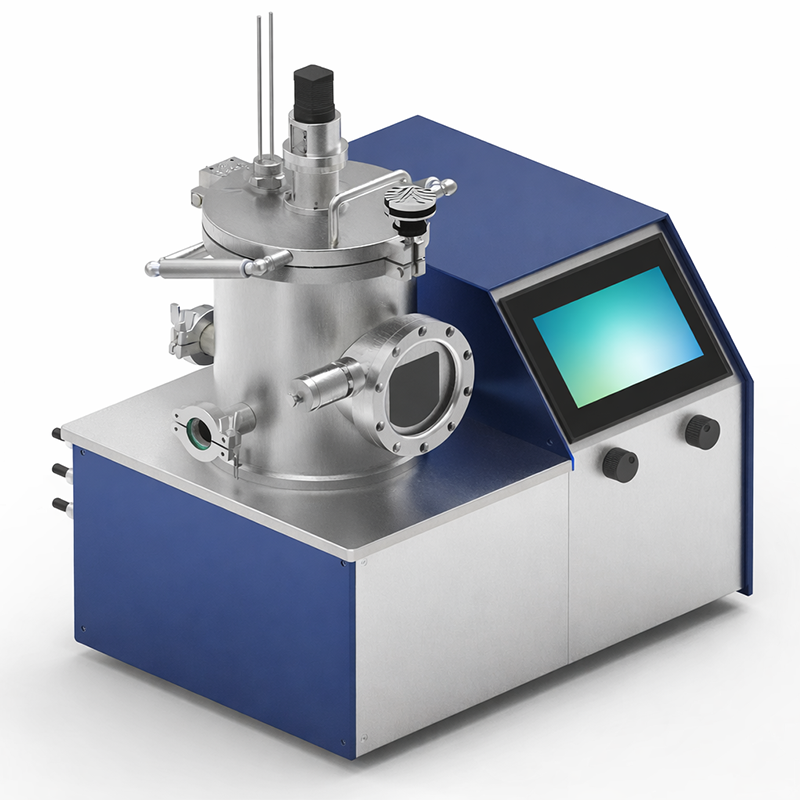

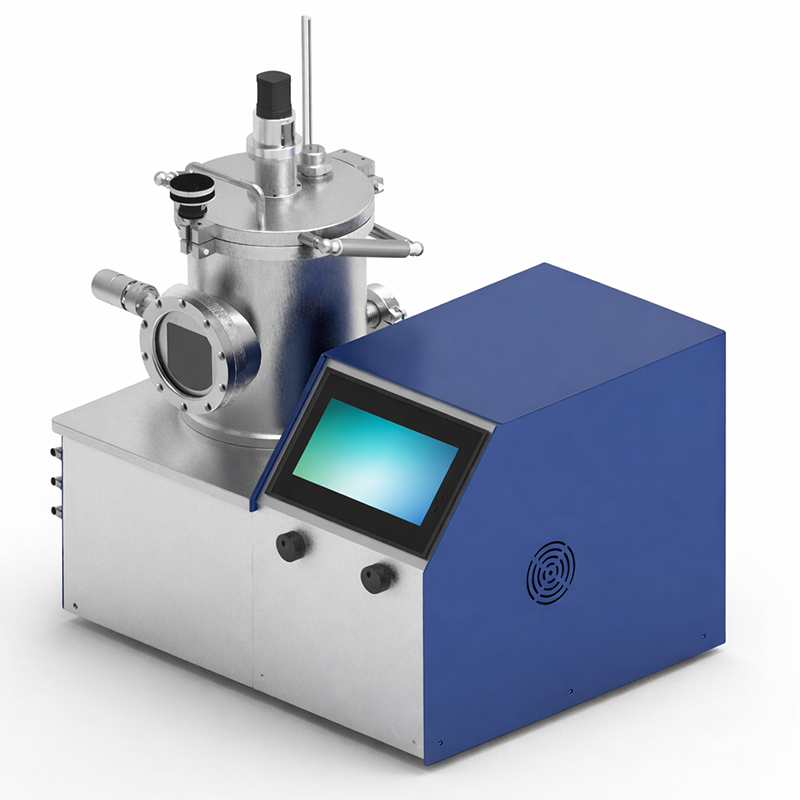

Product Description – KS-PVD-EVP180

The KS-PVD-EVP180 Small Thermal Evaporation Coating System features a rotatable substrate stage during the evaporation process, ensuring uniform deposition of thin film materials across the sample surface. The rotation mechanism significantly improves film thickness consistency and coating quality, making it suitable for precise thin film preparation.

The system is equipped with a tungsten boat evaporation unit, capable of accommodating strip, block, or powder evaporation materials, providing excellent flexibility for different coating requirements and material types.

A 7-inch TFT touch screen is integrated into the control system to display a fully graphical operating interface. The TFT display offers high responsiveness, high brightness, and high contrast, enabling intuitive touch operation and clear parameter visualization. The user-friendly interface allows operators to quickly understand and control the coating process, reducing training time and operational errors.

The KS-PVD-EVP180 is a high-vacuum thermal evaporation coating system, mainly composed of a vacuum system, vacuum measurement system, PLC + touch screen control system, and evaporation system. The ultimate vacuum level can reach 3.0 × 10⁻⁴ Torr, ensuring stable and high-quality thin film deposition.

Technical Parameters:

| Item | Specification |

| Model | KS-PVD-EVP180 |

| Equipment Type | Small Program Temperature-Controlled Thermal Evaporation Coating System |

| Vacuum Chamber | Φ180 × H200 mm |

| Chamber Material | High-purity quartz chamber with 304 stainless steel vacuum base |

| Vacuum System | High-speed dual-stage rotary vane vacuum pump + Pirani vacuum gauge |

| Ultimate Vacuum | ≤ 3 × 10⁻³ Pa (with molecular pump) |

| Vacuum Recovery Time | Reach 2 × 10¹ Pa within ≤ 10 minutes |

| Evaporation Source | Single evaporation source; compatible with metal and organic materials |

| Evaporation Power Supply | 1.0 kW vacuum evaporation power supply; manual and automatic constant current output |

| Substrate Stage | Ø60 mm substrate holder; quick disassembly; customizable mask plate; height adjustable (40 mm) |

| Deposition Rate & Thickness Monitoring | Thickness range: 1 Å – 9999 Å, resolution 1 Å |

| Rate range: 0.1 Å/s – 9999.9 Å/s, resolution 0.1 Å/s |

| Electrical Control System | Manual button control with relay logic |

| Alarm & Protection | Complete program interlock, anti-misoperation design, abnormal status alarm and protection |

| Power Supply | AC 220 V / 50 Hz |

| Total Power Consumption | ≤ 2 kW |

| Equipment Dimensions (W×D×H) | 440 × 330 × 630 mm |

| Net Weight | Approx. 60 kg |