Product

description.

The

KS-PVD-DP01 Dip Coating Machine is a precision instrument developed for the

research and production of thin films on glass substrates and silicon wafers,

particularly for applications involving the growth of nanometer-scale coatings

from liquid-phase materials. It is a product and an essential piece of

equipment for institutions engaged in research on liquid-phase film formation.

This machine is widely adopted by research institutes, laboratories, and

universities due to its reliability, precision, and ease of use.

The

KS-PVD-DP01 system integrates a high-precision stepper motor drive with a

motion control system independently developed by our team, enabling consistent

and stable lifting operations. The direction of movement can be conveniently

switched via a manual toggle button, allowing users to control upward and

downward motion based on their coating needs. The lifting speed and stroke can

be adjusted with high precision, ensuring accurate positioning and uniform

coating thickness during both immersion and withdrawal phases.

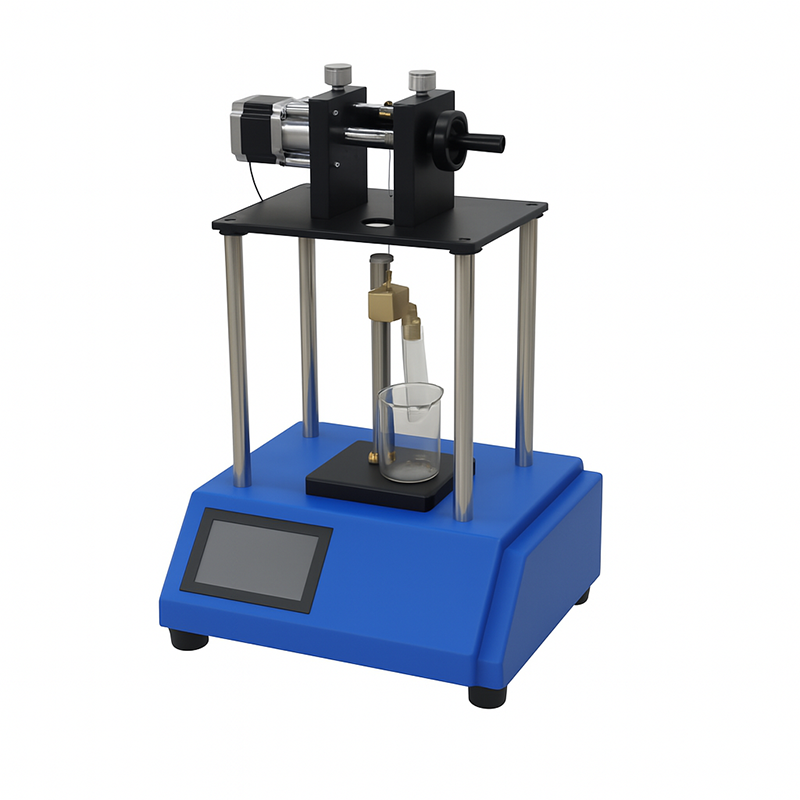

The

machine operates by immersing a sample substrate into a solution containing the

desired coating material. A smooth and consistent lifting motion ensures that

the substrate is evenly coated with a uniform thin film as it is withdrawn from

the solution. The KS-PVD-DP01 also allows manual control of immersion and

withdrawal through a conveniently positioned control panel. This flexibility is

particularly useful during the optimization phase of coating experiments, where

repeatability and real-time feedback are critical.

For

ease of use, the device features a touch-screen interface and clearly marked

operation buttons. It is designed for room-temperature operation and can be

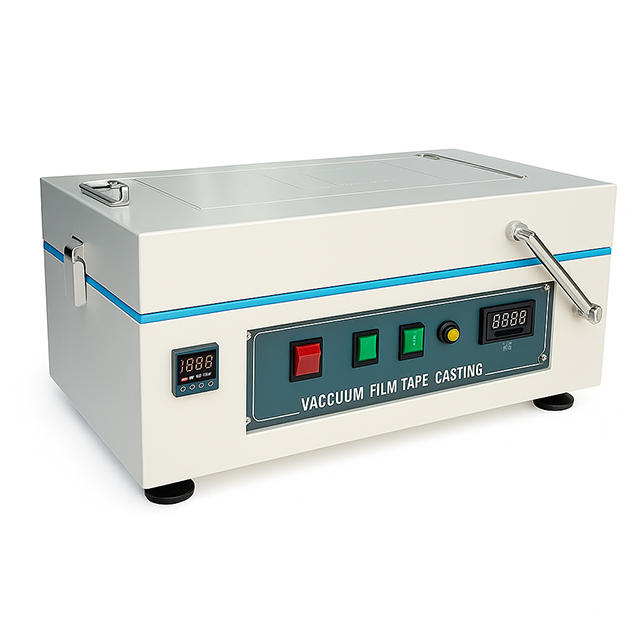

placed directly on a benchtop. For users who require dip-coating under

controlled temperature conditions, the KS-PVD-DP01 can be paired with an

optional temperature-controlled oven or vacuum chamber for advanced

experimental setups.

The

KS-PVD-DP01 offers excellent film uniformity by leveraging a silk-smooth

motorized lift to maintain constant speed, which minimizes turbulence and

solution instability. The result is a high-quality thin film with consistent

thickness across the entire surface. By adjusting the immersion depth, lifting

speed, and withdrawal speed, researchers can customize the film thickness to

meet various experimental requirements.

The

equipment is compact and space-saving, making it ideal for small and

medium-sized laboratories. Its user-friendly design ensures that both beginners

and experienced researchers can quickly master its operation. The modular

construction allows for easy maintenance and component replacement, enhancing

the system’s longevity and versatility.

Key

advantages of the KS-PVD-DP01 Dip Coating Machine include:

- Compact and simple

design: The system is easy to set up, operate, and relocate, making it

suitable for both entry-level and advanced users.

- Efficient and

space-saving: Its streamlined design minimizes space requirements while

maintaining full functionality.

- Precision motion control:

A high-precision stepper motor provides accurate and vibration-free linear

motion during the dip-coating process.

- Flexible operation:

Users can choose between automatic and manual modes, allowing fine control

during development or testing phases.

- Wide range of

applications: Ideal for research on photoresist coatings, sol-gel

processes, nanoparticle films, conductive layers, and organic/inorganic

hybrid materials.

In

conclusion, the KS-PVD-DP01 is a versatile and cost-effective solution for

laboratories focused on thin film deposition, material development, and coating

research. With its high performance, reliability, and intuitive operation, it

has become a standard tool in the fields of materials science, chemistry,

nanotechnology, and optoelectronics.

Technical

parameters.

| Product Name | KS-PVD-DP01 Dip Coating Machine |

| Product Model | KS-PVD-DP01 |

| Power Supply | AC220V 50/60Hz, standard 10A socket, good grounding required |

| Operating Environment | Temperature 25°C±15°C, Humidity 55%Rh±10%Rh |

| Lifting Motor Working Voltage | DC24V 3.75A (with power adapter) |

| Lifting Motor Power | 50W |

| Temperature Type | Room temperature |

| Drive Motor | High-precision stepping motor |

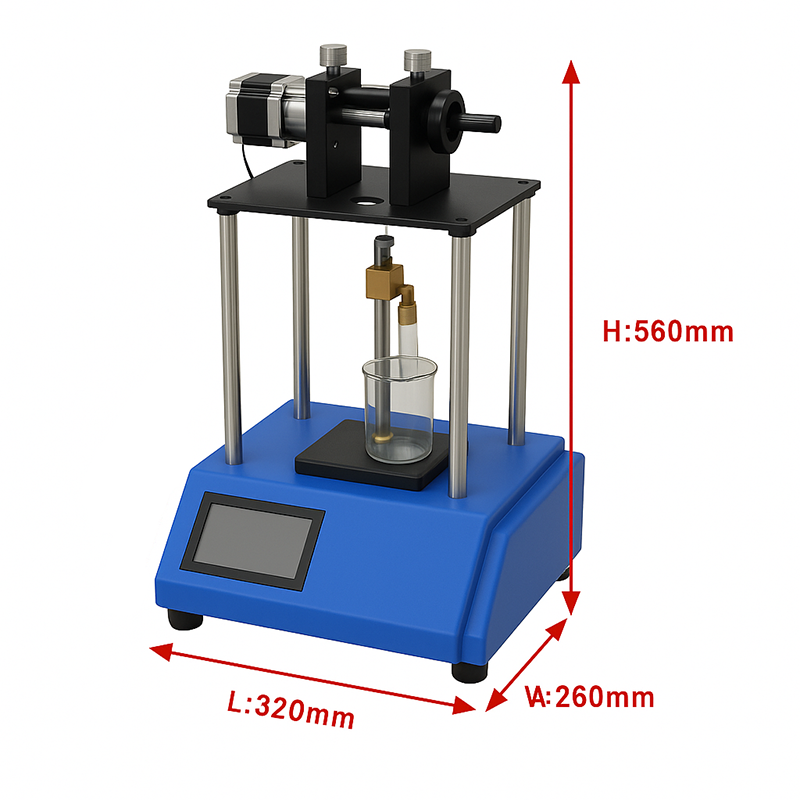

| Lifting Speed Range | 1–200 mm/min |

| Maximum Stroke of Sample Rack | 75 mm |

| Maximum Immersion Depth | ≤60 mm |

| Maximum Load Capacity | ≤100 g |

| Sample Size | 75 mm × 25 mm × 2.5 mm |

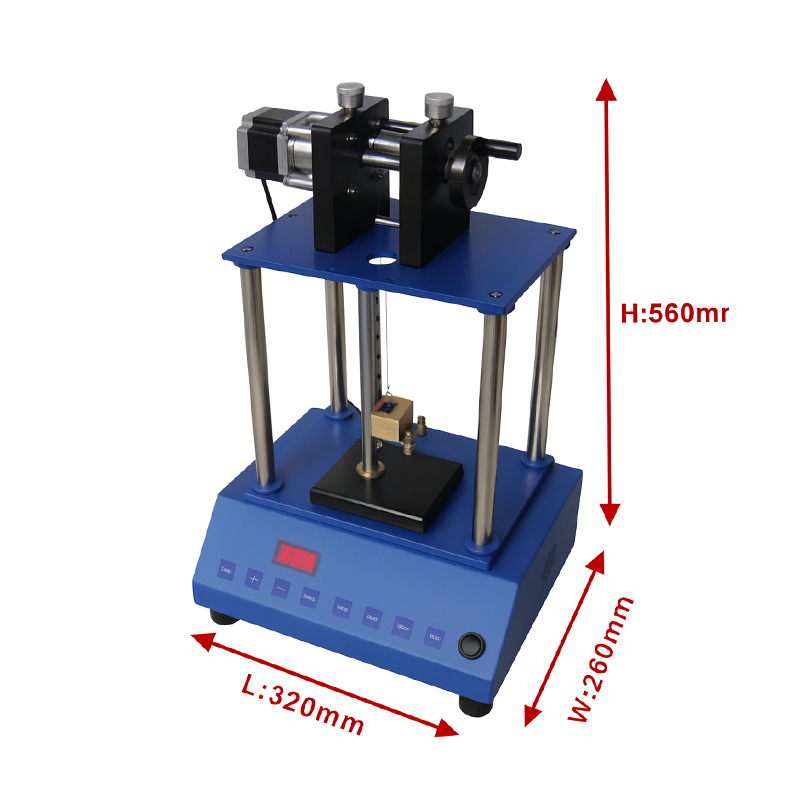

| Machine Dimensions | 320 mm × 260 mm × 560 mm |

| Net Weight | ~18 kg |