Product Description:

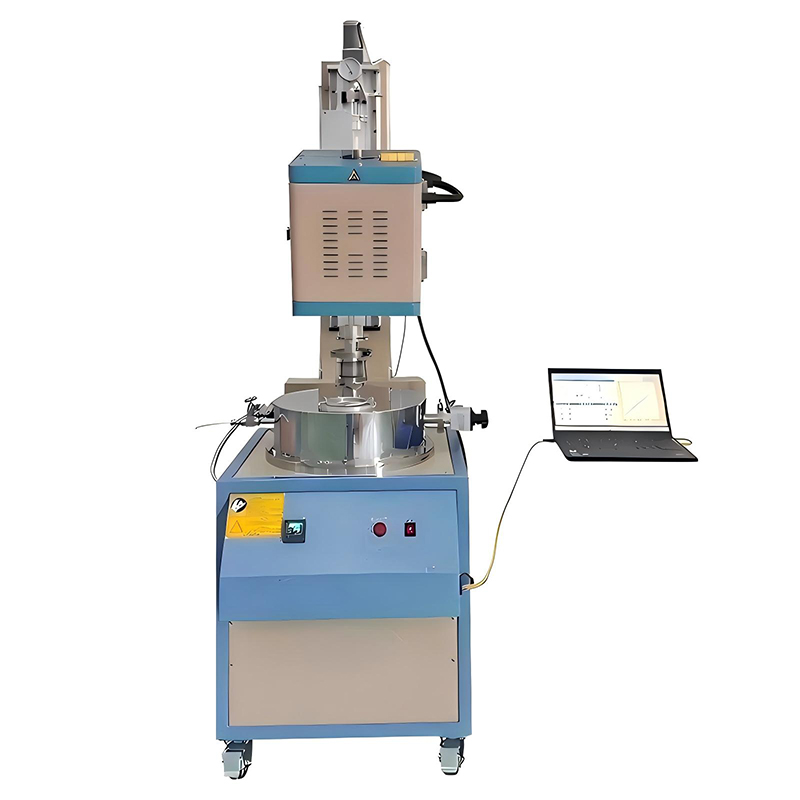

The KS-MFT-USP1200-V2Z is a vertically

structured, dual-zone ultrasonic spray pyrolysis furnace developed by Luoyang

Kunsheng Instrument Equipment Co., Ltd, designed specifically for

high-precision research in nanomaterial synthesis, thin film fabrication, and

aerosol-based thermal processes. This system combines advanced temperature

control with ultrasonic atomization to enable stable, efficient, and reproducible

pyrolysis of a wide range of precursor solutions.

Unlike traditional horizontal furnaces,

the vertical layout of the KS-MFT-USP1200-V2Z minimizes the risk of liquid

backflow and enhances the uniformity of material deposition along the heating

path. The design is ideal for experiments involving solution-based precursors,

including sol-gels, metal-organic compounds, and nanoparticle suspensions. The

vertical configuration also improves safety and cleanliness by allowing gravity

to assist in the smooth transport of aerosolized droplets through the thermal

zones.

A key advantage of this system is its

integrated ultrasonic nebulizer, which atomizes liquid precursors into fine

droplets using high-frequency vibration. These droplets are carried into the

heating chamber via carrier gas, where they undergo thermal decomposition,

crystallization, or other chemical transformations depending on the

application. This technology is particularly well-suited for generating uniform

nano- or microscale powders and coatings with controlled morphology.

The KS-MFT-USP1200-V2Z features two

independently controlled heating zones, allowing precise adjustment of the

temperature gradient along the processing tube. This dual-zone configuration

provides excellent flexibility for tailored thermal profiles, which is

essential for research in catalytic materials, energy storage, functional

coatings, and semiconductor precursors.

The system is compatible with vacuum or

inert gas atmospheres, making it highly adaptable for sensitive reactions. Its

modular sealing flanges and gas ports allow users to easily integrate pumps,

flow controllers, or custom accessories. Built-in protection mechanisms and

programmable logic contribute to safe, unattended operation—ideal for demanding

R&D environments.

With a user-friendly interface and

optional software for data logging and temperature profile management, the

KS-MFT-USP1200-V2Z provides not only performance but also convenience. Whether

used in academic laboratories, materials research institutes, or pilot-scale

innovation centers, this furnace supports a wide variety of applications that

require accurate thermal control and advanced aerosol processing.

Backed by Luoyang Kunsheng Instrument

Equipment Co., Ltd, a manufacturer committed to quality, precision, and

innovation, the KS-MFT-USP1200-V2Z represents a reliable, scalable solution for

next-generation materials processing.

Technical Parameters:

| Model | KS-MFT-USP1200-V2Z |

| Structure | Vertical dual-zone ultrasonic spray pyrolysis furnace |

| Power for Furnace | 6 KW total (3 KW per zone) |

| Voltage | AC 208–240V, Single Phase, 50/60 Hz |

| Max. Temperature | 1200°C (< 1 hour per zone) |

| Continuous Temperature | 1100°C per zone |

| Max. Heating Rate | ≤ 20°C/min |

| Temperature Accuracy | ±1°C |

| Heating Zone Length | Tube Size & Materials:Two stainless steel flanges with vacuum gauge and valves Top: Vacuum port with 1/4" barb connector Bottom: Gas inlet with 1/4" barb connector

|

| Vacuum Level | MET-certified, 30 programmable segments Built-in PID Auto-Tune, over-temperature & broken thermocouple protection RS485 communication port

|