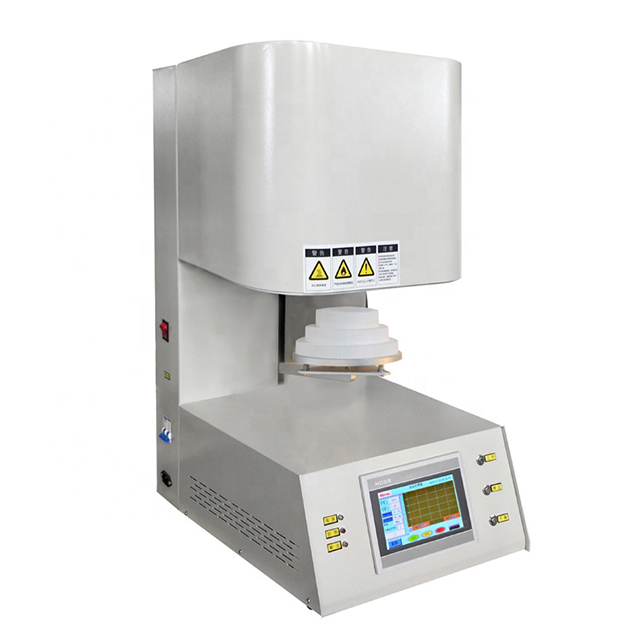

Product Description:

The KS-MFT-T1200-TGA compact tube

furnace with integrated thermal gravimetric analysis (TGA) function is an

advanced solution developed by Luoyang Kunsheng Instrument Equipment Co., Ltd

for precise thermal decomposition, material stability testing, and

compositional analysis under controlled atmospheric conditions. Designed for

research laboratories, materials science institutes, and industrial R&D

departments, this all-in-one system combines the accuracy of a high-performance

tube furnace with the sensitivity of a German-made precision electronic

balance.

This system features a split-type

compact furnace structure equipped with a high-purity quartz tube and alumina

fiber insulation to ensure superior thermal efficiency and minimal energy loss.

The furnace offers a maximum working temperature of 1200°C with flowing gas and

up to 1000°C under vacuum, making it suitable for a wide range of thermal

testing applications. Its 200 mm heating zone and 70 mm constant temperature

zone within ±10°C guarantee excellent thermal uniformity, while the ±0.1°C

precision temperature control supports even the most delicate thermal

processes.

At the core of the TGA function is a precision

electronic balance with 0.001 g resolution, enabling accurate real-time

measurement of sample mass changes during heating. With a capacity of 1–10

grams, researchers can monitor material behavior across various stages of

thermal processing. The sample crucibles, made of high-purity alumina, are

included in the system and offer both chemical stability and mechanical

strength under high temperatures.

The KS-MFT-T1200-TGA supports flexible

gas atmospheres and vacuum operation. It can achieve a vacuum level of 10⁻² Torr using a mechanical

pump and down to 10⁻⁵ Torr using an optional turbo molecular pump, offering

exceptional flexibility for oxidative and inert atmosphere studies. A quartz

observation window and gas inlet/outlet ports (KF25 standard) are provided for

real-time monitoring and easy gas flow control.

Temperature control is handled by an intelligent

Eurotherm controller with 10 programmable segments, allowing complex

temperature profiles to be executed automatically. Data from both temperature

and weight measurements can be logged and exported for further analysis, making

this system ideal for long-term experimental studies and quality assurance testing.

For laboratories seeking high-throughput

capabilities, Luoyang Kunsheng also offers optional automation modules,

including robotic sample handling for simultaneous operation of multiple

furnaces. This greatly improves productivity and experimental consistency,

especially in demanding research environments.

Safety, compliance, and user experience

are integral to the furnace design. With its compact footprint (700×600×1800

mm) and robust design, the KS-MFT-T1200-TGA fits seamlessly into modern lab

environments.

Whether you're conducting decomposition

analysis, residue studies, or compositional research under vacuum or gas, the KS-MFT-T1200-TGA

from Luoyang Kunsheng Instrument Equipment Co., Ltd is a dependable and

high-performance tool to advance your thermal research.

Technical parameters:

| Model | KS-MFT-T1200-TGA |

| Furnace Type | Split compact tube furnace with quartz tube |

| Heating Zone Length | 200 mm |

| Constant Temperature Zone | 70 mm within +/-10°C |

| Temperature Control Accuracy | ±0.1°C |

| Thermocouple Type | K Type |

| Power Supply | 220V AC, 50Hz |

| Max Power | 1500W |

| Max Temperature (Vacuum) | 1000°C |

| Max Temperature (Gas) | 1200°C |

| Max Heating Rate | ≤20°C/min |

| Temperature Controller | Eurotherm programmable controller |

| Control Segments | 10 programmable segments |

| Data Logging | Supported and exportable |

| Electronic Balance | Precision 0.001 g resolution |

| Sample Weight Range | 1 g to 10 g |

| Crucible | Four 8 mL alumina crucibles included |

| Vacuum Level (Mechanical Pump) | 10⁻² Torr |

| Vacuum Level (Turbo Pump) | 10⁻⁵ Torr |

| Automation Option | High-throughput robotic system available |

| Warranty | One-year limited (excluding consumables) |

| Dimension | 700*600*1800 mm |