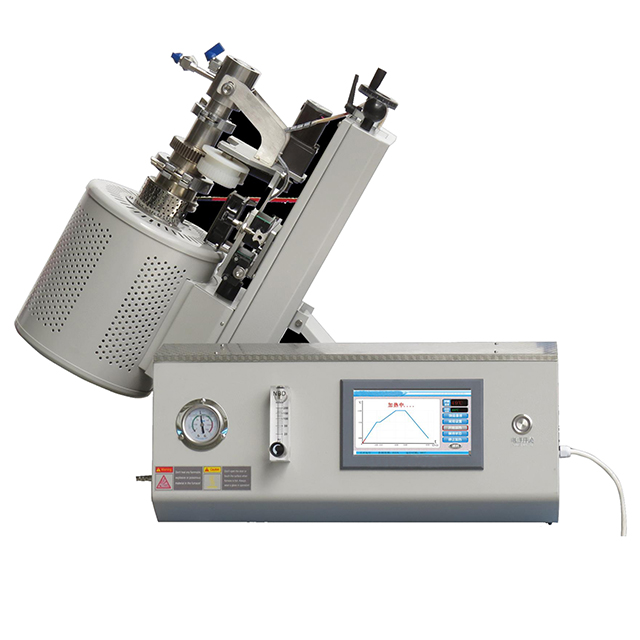

Vertical Fluidized Bed Tube Furnace with Customized Quartz Reactor

Precision Thermal Processing for Gas-Solid Reactions

The KS-FB1200-25 vertical fluidized bed tube furnace is a specialized thermal system designed for high-efficiency gas-solid interaction, nanoparticle synthesis, catalytic reaction studies, and thermal decomposition processes. Featuring a custom-shaped quartz reactor chamber, this furnace is ideal for advanced research tasks where uniform fluidization, precise temperature control, and clean reaction environments are essential. It is widely used in fields such as materials science, energy research, chemical engineering, and environmental technology.

At the heart of the system is a vertically mounted quartz reaction tube, which is engineered into a custom-shaped design to optimize fluid dynamics and material contact. The tube is typically fabricated from high-purity fused silica (quartz), offering excellent thermal stability, chemical resistance, and optical clarity. This unique reactor shape may include bulbous expansion zones, constricted necks, or diffusion baffles to support a stable and uniform fluidized bed formation.

The working principle of the KS-FB1200-25 vertical fluidized bed furnace is based on the introduction of process gases (such as nitrogen, argon, hydrogen, or air) from the bottom of the quartz tube through a porous distributor or gas inlet system. As the gas flows upward, it suspends fine powders or particulate samples inside the furnace, creating a fluidized bed. This fluidization dramatically improves heat and mass transfer between gas and solid phases, enabling faster and more uniform reactions compared to static tube furnaces.

The heating system is arranged concentrically around the vertical quartz chamber, using high-quality resistance heating elements or silicon carbide rods, depending on temperature requirements. A high-performance multi-layer insulation system ensures thermal efficiency and operator safety, while the heating zone is carefully calibrated to maintain uniform temperatures across the reaction bed.

Temperature control is achieved via an advanced PID controller with programmable temperature profiles. Users can define complex ramp and soak sequences to match their process needs. The system is compatible with thermocouples for accurate, real-time thermal feedback. Standard models offer maximum temperatures up to 1100°C, with working temperatures typically in the 600–1000°C range, depending on the materials and process gases used.

This furnace can be optionally equipped with:

Mass flow controllers for precise gas flow regulation

Vacuum pump interfaces for low-pressure or inert environment operations

Real-time data logging and remote monitoring via PC or touchscreen PLC

Gas cleaning or trapping systems to manage reaction by-products

The vertical structure of the furnace provides a compact footprint and efficient layout for gravity-driven sample loading and unloading. The custom-shaped quartz chamber is easy to replace or clean, minimizing cross-contamination between experiments and extending system life.

Applications of this vertical fluidized bed furnace include:

Nanoparticle synthesis and coating

Catalyst activation and evaluation

Gas-phase deposition or reaction kinetics research

Combustion and pyrolysis studies

Powder oxidation, reduction, or surface modification

Technical Parameters:

| Model No. | CY-FB1200-25 |

| Limiting temperature | 1200℃ |

| Working temperature | ≤1000℃ |

| Heating rate | 0-20℃/min |

| Heating zone length | 200mm |

| Constant heating zone | 60mm |

| Heating zone | Single zone |

| Tube diameter | 25mm, central diameter 50mm |

| Temperature accuracy | ± 1℃ |

| Heating element | Fe-Cr-Al alloy adopt by Mo |

| Max Power | 2.5kw |

| Temperature control | 30 steps programmable PID control |

| Chamber material | Alumina fiber |