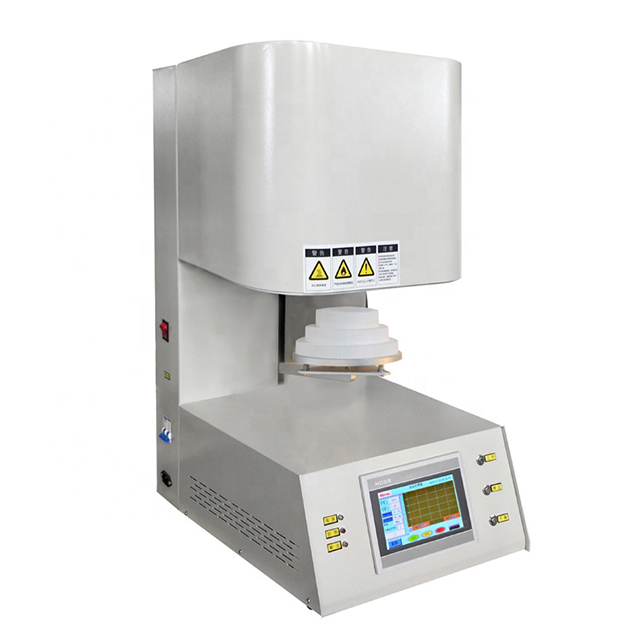

Product Description:

The KS-MFT-T1500-VT80 vertical tube

furnace, developed and manufactured by Luoyang Kunsheng Instrument Equipment

Co., Ltd, is a high-performance, precision-controlled thermal processing system

designed for advanced research and industrial applications. Engineered to meet

the demanding requirements of high-temperature materials synthesis, this

furnace integrates multiple cutting-edge features into a compact and reliable

unit.

This model features a vertically

oriented design that maximizes space efficiency while providing optimal thermal

distribution. Its robust construction and high-purity heating chamber allow for

stable, repeatable operation at extreme temperatures. What sets this system

apart is its capability to operate under high vacuum or controlled gas

atmospheres, making it suitable for a wide range of thermal treatments

including sintering, annealing, degassing, and material densification.

A unique advantage of the

KS-MFT-T1500-VT80 is its rotatable crucible holder, which enables in-situ

rotation of the sample under vacuum. This function ensures excellent

temperature uniformity and consistent sintering results by evenly exposing all

sides of the material to the heat source. The crucible is suspended inside the

vertical tube and can be easily lifted manually, allowing for effortless sample

loading and retrieval without disturbing the sealed environment.

The furnace is equipped with a

user-friendly programmable control system, featuring multi-segment temperature

control and real-time monitoring. Built-in safety mechanisms protect the system

from overheating or thermocouple failure, enabling safe, unattended operation.

Researchers can precisely define heating rates, dwell times, and cooling

profiles according to specific experimental needs. The inclusion of PC software

and a digital communication port ensures that process parameters can be logged,

analyzed, and remotely controlled.

Designed with durability in mind, the

heating chamber and insulation are built using high-grade refractory materials

to extend service life and reduce maintenance needs. The integrated

water-cooled flanges and optional vacuum pumps make this furnace ready for a

variety of working environments, from standard atmospheric pressure to

high-vacuum operations. This makes it ideal for universities, research

laboratories, and high-tech industries working on ceramics, powder metallurgy,

composite materials, or semiconductor materials.

Luoyang Kunsheng Instrument Equipment

Co., Ltd is committed to providing innovative thermal solutions tailored to the

evolving demands of modern material science. The KS-MFT-T1500-VT80 is a

testament to this commitment, combining performance, reliability, and

operator-friendly features in one system. Whether you're engaged in

experimental R&D or small-scale production, this furnace offers the

precision and flexibility required to achieve superior results.

Technical Parameters:

| Model | KS-MFT-T1500-VT80 |

| Power | 5.5 KW |

| Voltage | AC 208–240V Single Phase, 50/60 Hz |

| Max. Temperature | 1500℃ < 30 minutes |

| Continuous Temperature | 1400℃ continuous |

| Max. Heating Rate | ≤ 10℃/min |

| Heating Element | 1500℃ grade SiC, 12 pcs |

| Tube Material | Mullite tube made in the USA |

| Tube Size | OD 84 mm × ID 72 mm × Length 1393 mm |

| Heating Zone Length | 440 mm |

| Constant Temperature Zone | 150 mm ±1℃ |

| Temperature Control | 30 programmable segments, PID auto-tune |

| Temperature Accuracy | ±1℃ |

| Thermocouples | Five K-type (one per zone) |

| Communications | RS485 port included |

| Software | PC control software and interface module included |

| Vacuum Flanges | 80 mm water-cooled stainless steel flanges with gauge and valves |

| Water Chiller | 16 L/min recirculating chiller included |

| Vacuum Level (Mechanical Pump) | 10⁻³ Torr |

| Vacuum Level (Turbopump) | 10⁻⁵ Torr |

| Additional Heating Element | Fe-Cr-Al alloy doped with Mo |

| Power Cable | 10 feet, 10-3 AWG UL-approved heavy-duty cable |

| Plug | Not included (can be ordered separately) |