Product Description:

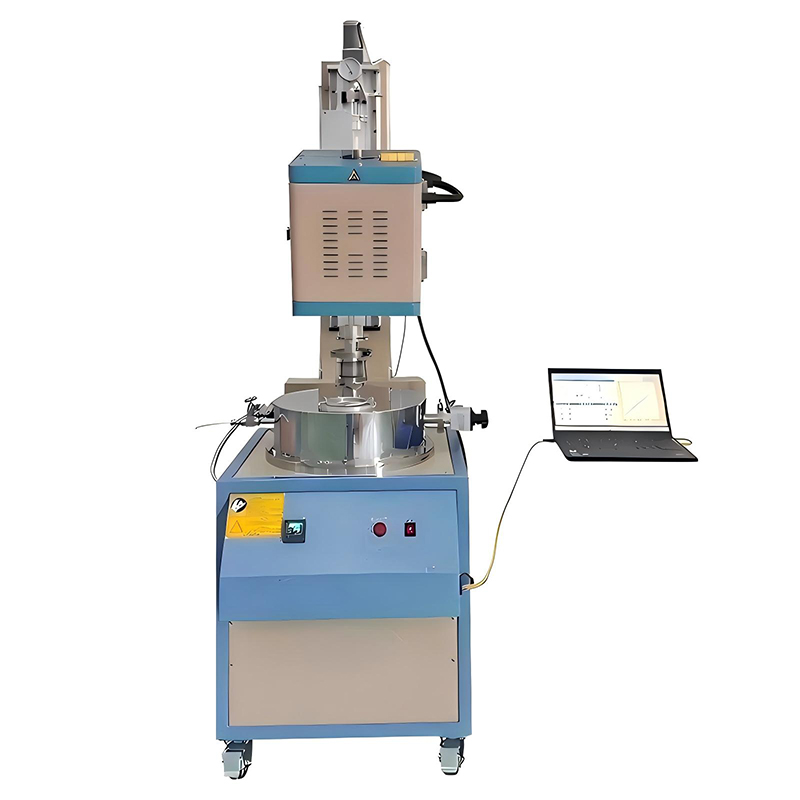

The KS-MFT-USP1200-3Z is a

high-performance three-zone ultrasonic spray pyrolysis furnace developed by

Luoyang Kunsheng Instrument Equipment Co., Ltd, tailored for advanced research

in nanomaterials synthesis, thin film deposition, catalyst preparation, and

aerosol-assisted chemical processing. This system integrates ultrasonic

atomization, precise thermal control, and efficient nanoparticle collection

into one compact, reliable platform.

At the heart of the system is an

ultrasonic spray generator operating at 1.7 MHz, capable of producing fine

aerosols from various precursors including metal salts, sol-gel solutions, and

colloids. These fine droplets are introduced into the furnace chamber through a

controlled gas stream, allowing the material to undergo decomposition and phase

transformation as it travels through the heated zones. This method offers

superior control over particle morphology and chemical composition compared to

conventional spray pyrolysis systems.

The KS-MFT-USP1200-3Z features a

three-zone tubular furnace design, ensuring a highly uniform and adjustable

temperature profile along the processing path. The tube furnace is capable of

supporting a smooth temperature gradient, making it suitable for complex

reaction sequences, multilayer coatings, and continuous material synthesis.

Each zone is independently controlled, allowing researchers to tailor the

heating profile to their specific reaction requirements.

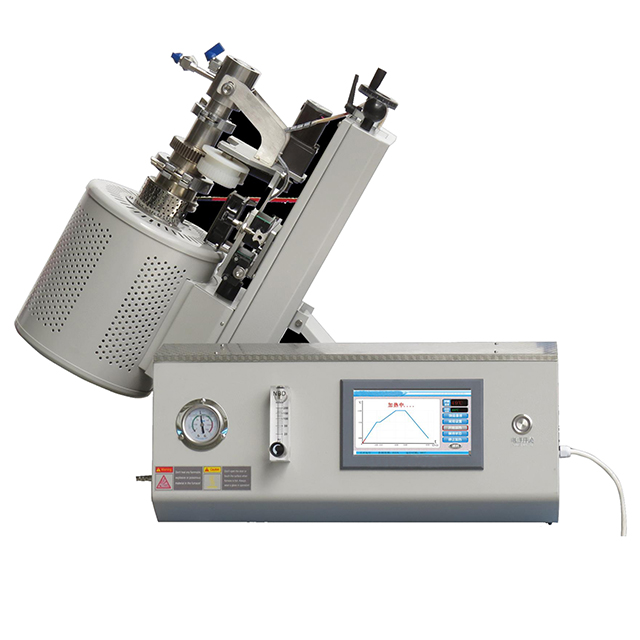

Unlike standard furnaces, this system

also includes a dedicated atomizing module equipped with a stainless steel

liquid container, liquid injection pump, flow meter, and sealed aerosol

delivery system. The integration of this atomizer with the furnace guarantees

minimal precursor waste and excellent consistency in particle production. It is

particularly suitable for applications requiring high-purity powders and

submicron or nanoscale particles, such as battery materials, ceramic coatings,

or photonic structures.

To maximize safety and productivity, the

furnace chamber is mounted on an adjustable tilting frame. This prevents liquid

backflow, enhances the stability of aerosol movement, and improves user

ergonomics during loading and maintenance. Furthermore, the exhaust side of the

furnace is equipped with a high-voltage electrostatic nanoparticle collector,

effectively capturing particles from the gas flow while maintaining low

contamination risk. This enhances yield and ensures a clean operating

environment for sensitive processes.

The KS-MFT-USP1200-3Z system is built

for both academic research and industrial R&D environments, supporting

consistent operation, intuitive control, and flexible configuration. Whether

you are working on the scalable production of nanopowders or pioneering new

functional materials, this system delivers the thermal precision and aerosol

control necessary for breakthrough innovation.

Luoyang Kunsheng Instrument Equipment

Co., Ltd is committed to delivering advanced laboratory equipment that empowers

scientists and engineers across disciplines. With decades of experience in

thermal processing and materials engineering, our design philosophy emphasizes

functionality, precision, and safety—reflected in every component of the

KS-MFT-USP1200-3Z system.

Technical Parameters:

| Model | KS-MFT-USP1200-3Z |

| Voltage & Power | Single Phase, 208–240V AC, 50/60Hz, Max. 7KW |

| Working Temperature | 1100°C continuous, 1200°C < 1 hour |

| Max. Heating / Cooling Rate | < 20°C/min |

| Heating Zone | Three heating zones, 300 + 300 + 300 mm (900 mm total) |

| Constant Temperature Zone | 600 mm ±2°C (when all zones are set to the same temperature) |

| Heating Elements | Fe-Cr-Al alloy doped with Mo |

| Temperature Controller | Three digital temperature controllers with 30 programmable segments |

| Temperature Accuracy | ±1°C standard, optional Eurotherm controller with ±0.1°C accuracy |

| Aerosol Generator | 1.7 MHz ultrasonic generator, 220V AC, 8 power levels adjustable |

| Liquid Injection Pump Flow Rate | 0.004 – 70 ml/min |

| Carrier Gas Flow Meter Range | 0 – 200 SCCM |

| Processing Tube | Quartz tube, OD 25 mm, length 1400 mm |

| Vacuum Compatibility | KF25 flanges, supports external vacuum pump |

| Electrostatic Precipitator | 30KV high voltage, dual-layer design, KF25 ports included |

| Net Weight | Approx. 150 Kg |