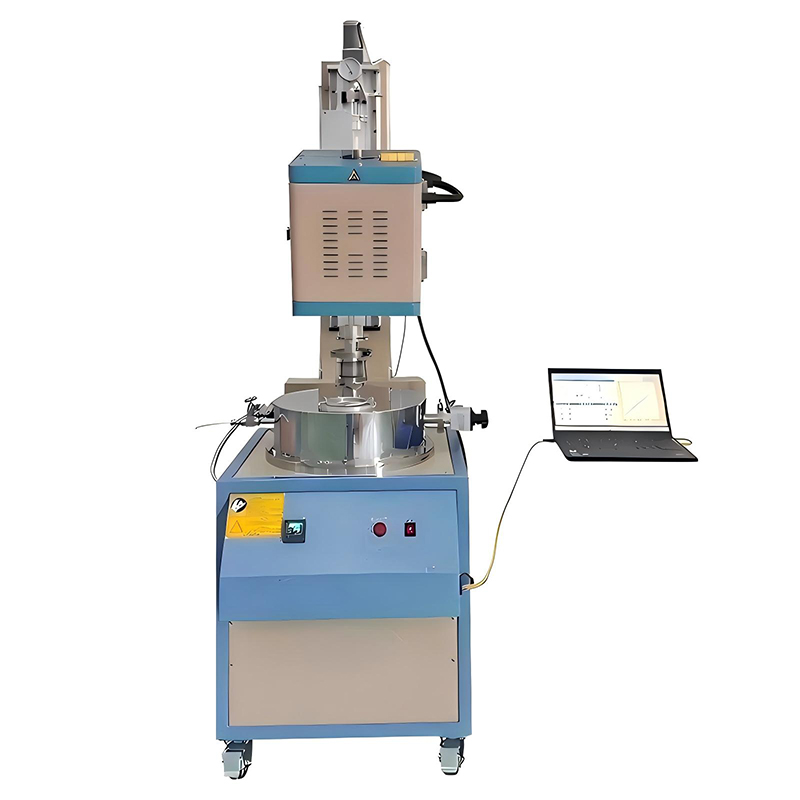

Product Description:

The six-position fusion furnace developed by Luoyang Kunsheng Instrument Equipment Co., Ltd is a high-efficiency system designed specifically for X-ray fluorescence (XRF) sample preparation. It features an advanced AI-controlled heating system capable of reaching temperatures up to 1300°C, with a rapid heating rate of ≥40°C per minute. The furnace ensures precise thermal control with an accuracy of ±1°C, using an S-type platinum-rhodium thermocouple for stable and reliable temperature monitoring.

This model can process six samples simultaneously, significantly improving laboratory throughput. The system allows for customized melting times and provides multiple holding time settings before, during, and after melting. Its modular design includes adjustable crucible tilting angles and a rotating support platform with stepless speed control, ensuring uniform melting and thorough mixing. Reversible rotation and programmable motion profiles enhance the consistency and repeatability of results.

The transparent workflow allows operators to add release agents to the crucibles before melting. Once the lid is opened, the crucibles are placed on the rotating support, and the automated sequence takes over, handling the melting process with minimal supervision. Each sample typically weighs around 80–90g, and the equipment supports continuous processing with a throughput of up to 10 cycles per hour.

Engineered for reliability and ease of use, the unit includes optional features such as a pressure-loading system and additional safety mechanisms for industrial and research use. The robust build, compact footprint, and intelligent control system make it ideal for laboratories, universities, mining companies, and material testing facilities that require accurate and high-volume sample preparation for XRF or other elemental analysis techniques.

Technical Parameters:

| Product Model | KS-MFT-M6 six position melting furnace |

| Control System | AI intelligent control |

| Dimensions (L×W×H) | 1100mm × 620mm × 1050mm |

| Heating Rate | ≥ 40°C/min (preheating available) |

| Operating Temperature | 0–1300°C |

| Temperature Accuracy | ±1°C at holding (S-type thermocouple) |

| Number of Stations | 6 positions (one-time molding, can be customized) |

| Sample Melting Time | 10–15 min/6 samples (may vary by material) |

| Pouring Angle Adjustment | 0–40° adjustable |

| Rotation Speed of Support | 0–25 rpm (stepless adjustable, reversible) |

| Optional | Upper pressure system available |

| Sample Weight | 80–90g per crucible |

| Throughput | Supports 10 sets of workpieces per hour |

| Melting Time Settings | Optional |

| Pre-Melting Holding Time | 0–160 min adjustable |

| Melting Holding Time | 0–160 min adjustable |

| Post-Melting Holding Time | 0–160 min adjustable |

| Machine Weight | Approx. 360 kg |

| Power Consumption | 10kW (typically 3–5kW) |

| Power Supply | Heating unit 380V, Control system 220V |

| Rated Current | 30A |

| Rated Frequency | 50Hz |