Product Description:

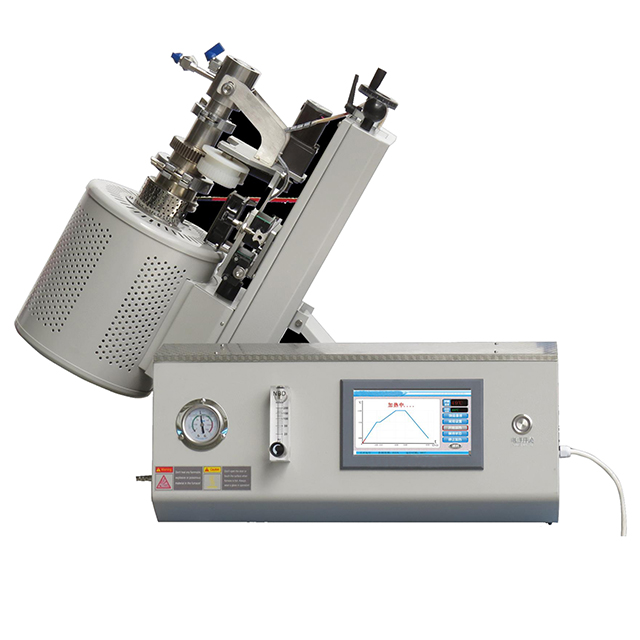

The KS-MFT-T1200-TGA50 Thermogravimetric

Analyzer, developed and manufactured by Luoyang Kunsheng Instrument Equipment

Co., Ltd, is a high-performance system designed for accurate, real-time

analysis of material weight changes under controlled thermal conditions. This

advanced instrument is ideal for research and industrial laboratories seeking

precision in the study of thermal stability, decomposition behavior, oxidation,

and reduction characteristics of a wide range of materials.

Built with versatility and reliability

in mind, the KS-MFT-T1200-TGA50 integrates advanced force sensing technology

with a controlled thermal environment to deliver highly accurate and repeatable

results. The system features an integrated vertical tube furnace that can be

configured with different tube materials based on the application requirements,

allowing users to choose optimal compatibility for specific temperature ranges

and chemical environments.

The analyzer includes a precision load

cell that continuously monitors mass changes of samples during the entire

heating process. This enables users to precisely characterize the thermal

degradation, reaction kinetics, or compositional analysis of materials such as

powders, composites, polymers, ceramics, and metals. Its real-time data output

can be linked to PLC or PC systems, making it suitable for both standalone

operation and integration into complex experimental workflows.

To ensure consistent and stable

temperature control, the KS-MFT-T1200-TGA50 is equipped with a programmable

temperature controller featuring intelligent PID tuning and automatic safety

features. These capabilities protect against overheating and sensor malfunction,

making the unit safe for unattended operation while maintaining exact thermal

profiles for testing.

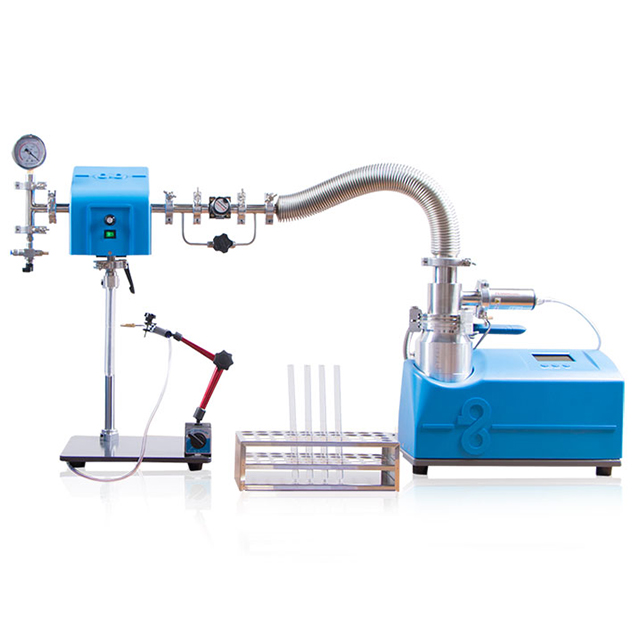

The system supports vacuum and gas

atmosphere operations, making it ideal for thermogravimetric analysis in inert

or reactive environments. With built-in ports for vacuum pumps and gas flow

systems, users can easily simulate specific testing conditions such as

oxidation, reduction, or inert atmosphere decomposition. Optional mass flow

controllers and gas delivery systems can also be connected to achieve precise

control over the test environment.

Every unit comes with a high-purity

alumina crucible suitable for general use. For specialized applications,

alternative crucible materials such as zirconia, boron nitride, or

yttria-stabilized zirconia can be selected, ensuring chemical compatibility and

structural integrity at various temperature levels. Customized crucibles are

available on request to meet specific experimental needs.

For researchers and engineers seeking

seamless data acquisition and analysis, the KS-MFT-T1200-TGA50 includes

comprehensive PC software and communication modules that allow for automated

control, data logging, and real-time visualization of the weight change curves.

This streamlines data collection and enhances the repeatability of results,

making the instrument an ideal choice for advanced materials research, quality

control, and academic studies.

Backed by a dependable support system

and a one-year limited warranty, Luoyang Kunsheng Instrument Equipment Co., Ltd

ensures that users not only receive a high-quality analytical tool but also

benefit from responsive service and customization support. Whether for

fundamental material research or demanding industrial testing, the

KS-MFT-T1200-TGA50 offers the precision, adaptability, and reliability that

professionals require.

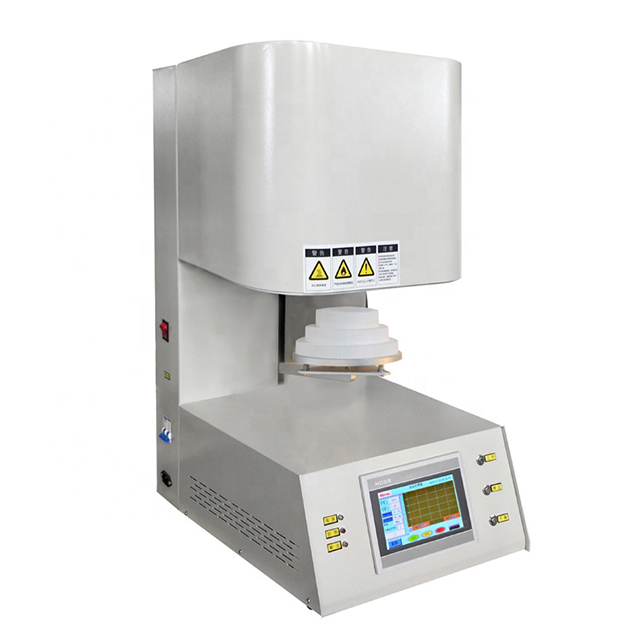

Technical parameters:

| Product Model | KS-MFT-T1200-TGA50 |

| Max. Temperature | 1200 - 1700 selectable |

| Power | 208 - 240VAC, single phase, 50 / 60 Hz |

| Power Consumption | 4 KW for 1200°C, 6 KW for 1700°C |

| Power Cable | 3 meters included, without plug |

| Tube Size | 2" OD - 3.2" OD selectable |

| Tube Material | Quartz for <1200°C, Mullite for <1500°C, Alumina for <1700°C |

| Force Sensor Accuracy | 0.05% |

| Sample Weight Range | 1 g to 100 g (based on Fe powder) |

| Sensor Output | Connects to PLC or PC for weight change curve display |

| Included Crucible | One alumina crucible included |

| Optional Crucible | ZrO2, BN, or Y2O3 crucibles available upon request |

| Temperature Controller | Eurotherm-3000 programmable controller |

| Controller Features | PID Auto-Tune, overheat & broken thermocouple protection |

| Temperature Accuracy | +/- 0.1°C |

| Thermocouple Type | B-type, touches crucible bottom |

| Communication Port | RS485 |

| Software | PC control software and interface module included |

| Vacuum Port | KF25 port built-in |

| Vacuum Level | Depends on selected pump |

| Gas Inlet/Outlet | 1/4" built-in, <200 sccm flow rate recommended |

| Gas Delivery | Compatible with MTI gas delivery system or gas analyzer |

| Warranty | One-year limited (excluding consumables like tubes and o-rings) |