Product

Description:

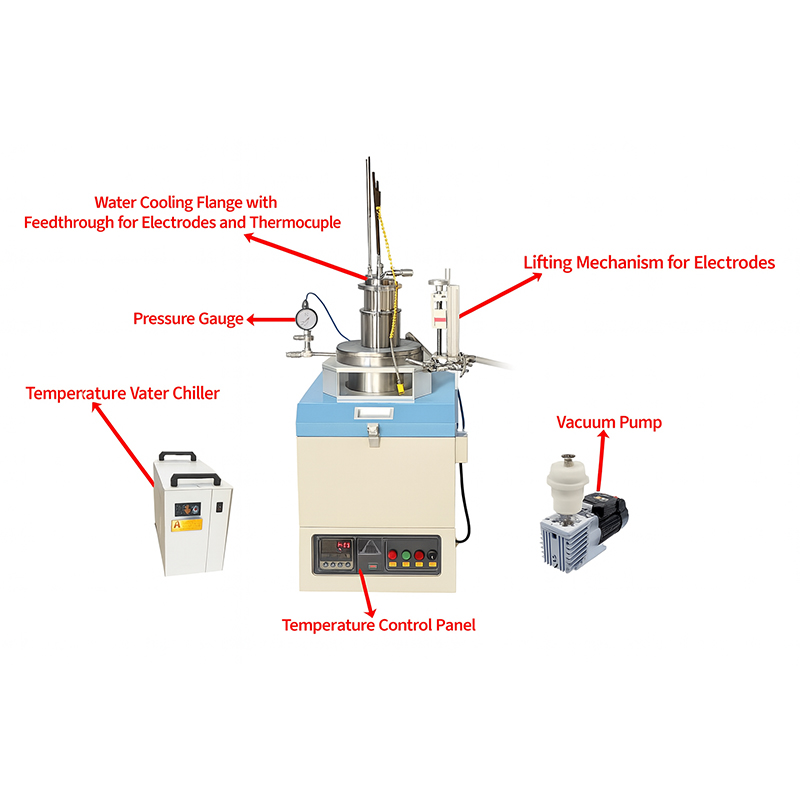

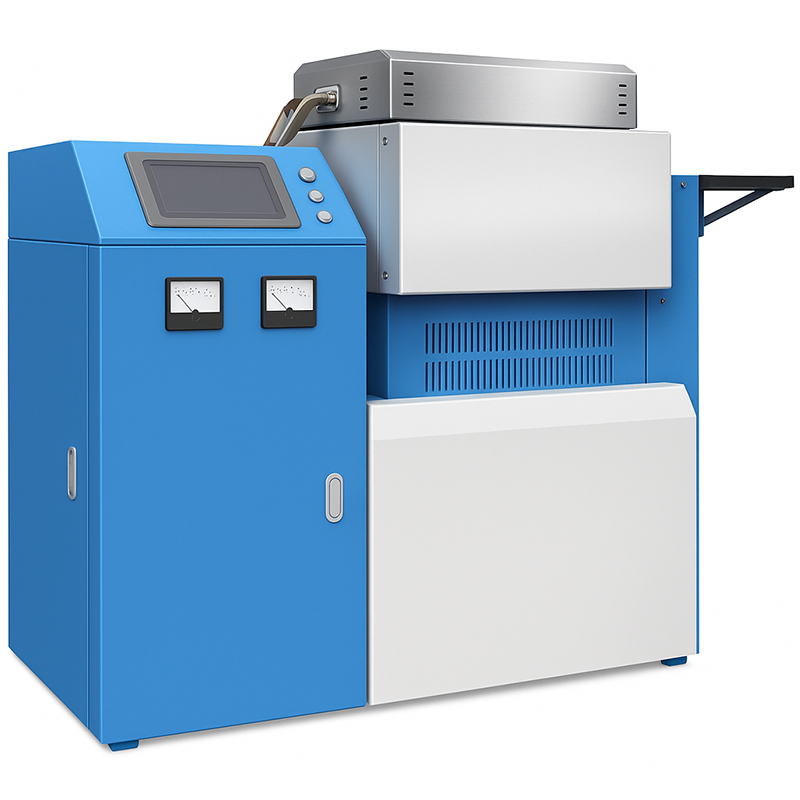

The KS-MFT-MSE1200

Molten Salt Electrolysis Furnace is a high-performance thermal processing

system designed for advanced materials research and high-temperature

electrochemical experiments. This unit is specifically engineered for molten

salt electrolysis applications, enabling users to conduct controlled

electrochemical reactions at elevated temperatures in a safe, precise, and

repeatable environment.

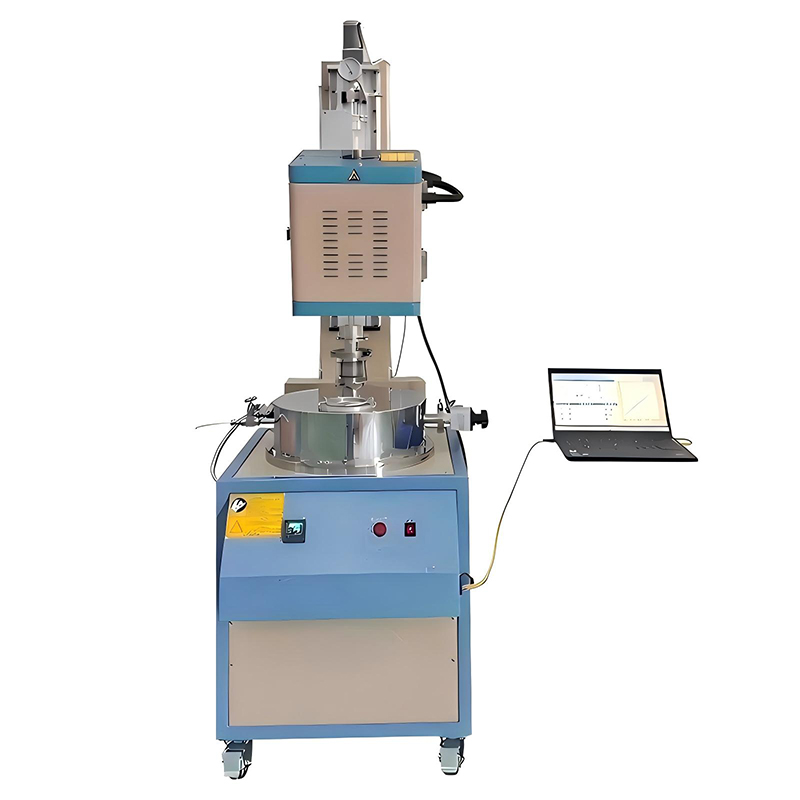

This

model adopts a top-loading structure, integrating an advanced quartz reaction

chamber and highly efficient insulation layers to provide uniform temperature

distribution and minimized heat loss. The system is built with industrial-grade

reliability and is ideal for both laboratory-scale synthesis and pilot-scale

testing of novel materials, including metal reduction, oxide conversion, and

electrochemical deposition.

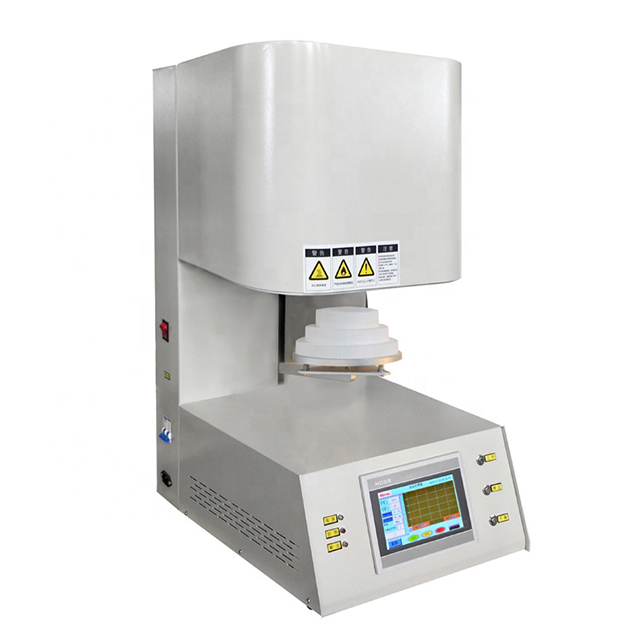

At

the core of the KS-MFT-MSE1200 is its precision control system. Equipped with a

multi-segment programmable temperature controller, it allows the user to define

complex heating profiles with ramp/soak functionality for precise thermal

control. This feature ensures that electrochemical reactions occur under

optimal thermal conditions, which is critical when dealing with sensitive

molten salt chemistry.

To

facilitate in-situ temperature monitoring and control, the system includes dual

thermocouple support, one dedicated to chamber temperature and another optional

channel for electrolyte or crucible monitoring. The furnace is also equipped

with automatic safety interlocks to prevent overheating and sensor failure,

providing a reliable and secure operating environment.

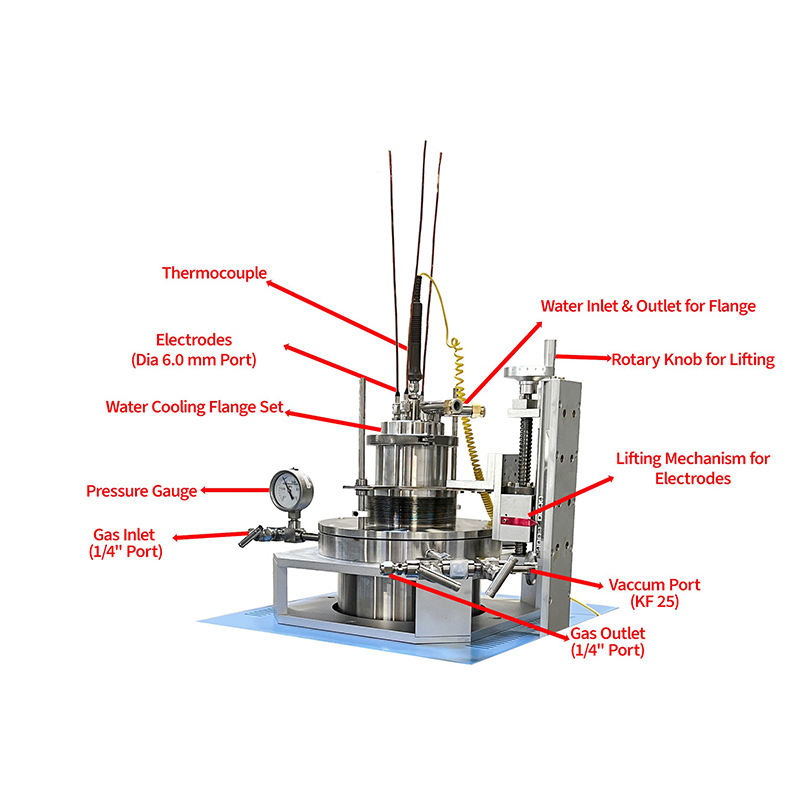

One

of the distinguishing features of this model is its modular electrode

configuration. The KS-MFT-MSE1200 incorporates a water-cooled top flange with

multiple feedthroughs, allowing users to install copper or graphite electrodes

for electrolysis. The integrated electrode lifting mechanism ensures accurate

positioning and height adjustment, which is essential for consistent current

distribution during electrochemical operations.

The

quartz crucible used within the system serves as the primary reactor for

holding molten salts. Its excellent chemical resistance and high thermal

stability make it ideal for handling aggressive electrolytes such as chlorides,

fluorides, and carbonates. A dedicated electrode alignment frame is also

included to simplify setup and enhance reproducibility between runs.

For

temperature control and chamber cooling, the system is designed to work with an

external recirculating water chiller. This ensures the upper flange and

feedthroughs remain within operational temperature limits even during

long-duration experiments. Additionally, for processes involving gas atmosphere

control or vacuum purging, the KS-MFT-MSE1200 can be optionally configured with

a vacuum pump to support inert or low-pressure conditions.

The

furnace body is constructed from powder-coated steel and high-temperature

insulation material, combining robust mechanical strength with thermal

efficiency. Its clean industrial design ensures easy access to all operational

components while maintaining a compact footprint suitable for space-limited

laboratories.

Applications

of the KS-MFT-MSE1200 span a wide range of material synthesis and

electrochemical investigations. Researchers use it to explore electrorefining

of metals, production of reactive rare-earth elements, and high-temperature

corrosion studies. It's also widely applied in nuclear materials processing,

battery materials research, and the recovery of strategic metals from molten

salts.

Overall,

the KS-MFT-MSE1200 is a comprehensive and versatile solution for molten salt

electrolysis studies. With its thoughtful design, intelligent controls, and

application-focused engineering, it meets the demanding requirements of modern

research institutions, universities, and industrial laboratories seeking

innovation in high-temperature electrochemical processes.

Technical

parameters:

| Model | KS-MFT-MSE1200 |

| Power Supply | 208–240 VAC, 1 phase, 50/60 Hz, 20 A |

| Max Power | 4 kW |

| Furnace Type | Top loading box furnace |

| Max Working Temperature | ≤1100°C |

| Heating Rate | ≤20°C/min |

| Heating Area | Φ240 × 245 mm |

| Heating Chamber | One-side open quartz tube Φ200 × 425 mm |

| Optional Chamber | SS 310 chamber for operation <900°C |

| Temperature Controller | PID auto control with ±1°C accuracy and 50 programmable segments |

| Safety Features | Interlocks for overheating and thermocouple failure |

| Thermocouple | K type for furnace temperature control |

| Optional Thermocouple | K type for in-situ temperature monitor |

| Crucible | Quartz crucible Φ120 × 114 × 150 mm |

| Electrode Frame | Quartz positioning frame for electrode alignment |

| Electrodes | Three 1/8" copper electrode feedthrough with adaptors for Ø6 mm electrodes |

| Fittings | 1/4" compression tube fittings |

| Thermal Block | Alumina foam block Φ190 mm × 60 mm H |

| Chamber Pressure | <3 psig |

| Water Cooling | Required for vacuum flange |

| Water Chiller (Optional) | CW5000 or equivalent |

| Vacuum Pump (Optional) | 156 L/min or equivalent, pressure <5e-2 torr |