Product Description:

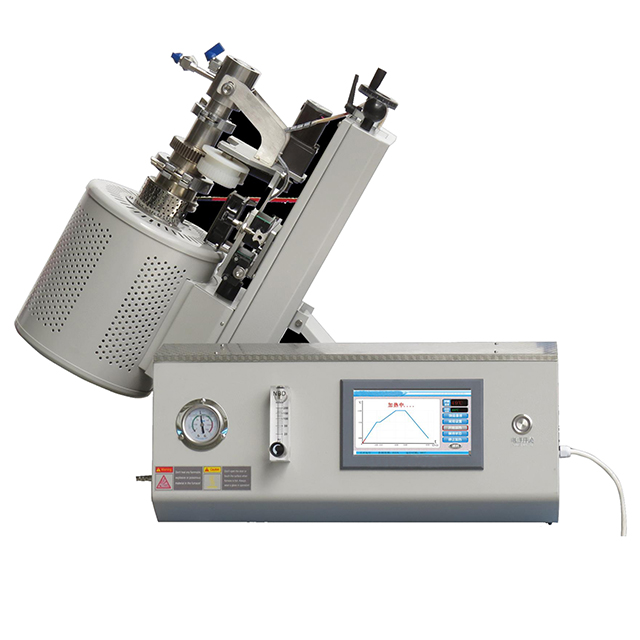

The KS-MFT-FB1200-3Z is a

state-of-the-art three-zone vertical fluidized bed tube furnace developed by Luoyang

Kunsheng Instrument Equipment Co., Ltd, specifically engineered for

high-temperature catalytic gas-solid reactions such as Methane Reforming and Fischer-Tropsch

Synthesis. This advanced system integrates precise thermal control, robust

construction, and modular gas handling capabilities, making it a powerful

platform for reaction kinetics research, catalyst screening, and syngas

production studies.

The system features a three-zone

vertical furnace with a total heating length of 900 mm (300 mm per zone),

allowing for uniform and flexible temperature control along the reactor column.

Each zone is independently managed through digital temperature controllers,

with up to 50 programmable steps for accurate heating, soaking, and cooling

cycles. The maximum operating temperature reaches 1200°C (short-term) with

continuous operation up to 1100°C, making it suitable for high-temperature

reforming and long-duration catalytic experiments.

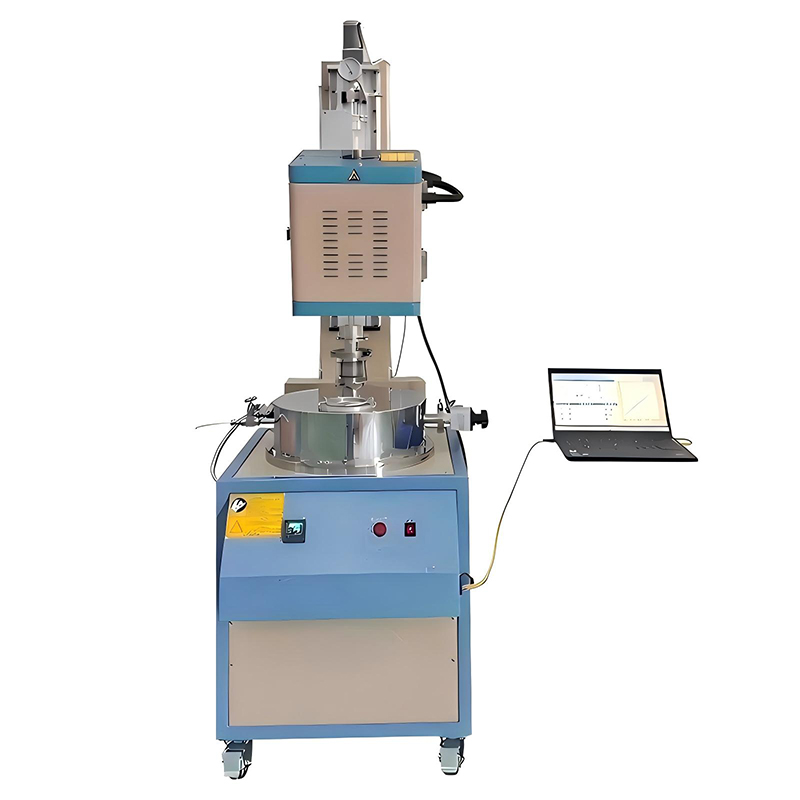

At the core of this furnace is a fluidized

bed reactor, designed to improve gas-solid contact, heat transfer efficiency,

and catalyst utilization. The included frits and mesh distribution plates

create a controlled fluidization zone within the quartz or alloy reactor tubes,

allowing precise regulation of gas flow and particle suspension. This setup is

particularly beneficial for endothermic reactions such as steam methane

reforming (SMR) and dry reforming, where efficient heat and mass transfer are

essential.

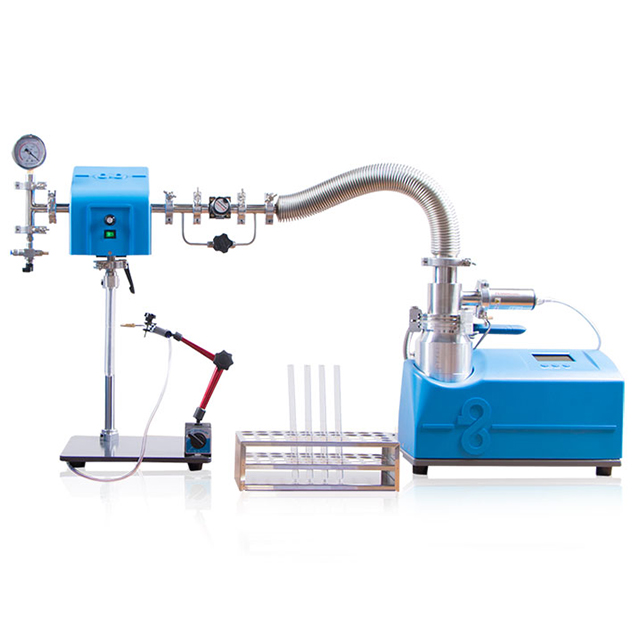

A gas pre-heating unit is integrated

into the system, featuring a 316L stainless steel spiral tube furnace with a

400 mm heating zone. It can preheat reactant gases up to 700°C before they

enter the main reaction tube, ensuring stable reaction initiation and improved

thermal control. This is especially critical for Fischer-Tropsch processes that

require precisely conditioned syngas feeds.

The furnace accommodates both quartz and

nickel-base alloy tubes, depending on the pressure and chemical compatibility

requirements. The alloy tube version supports high-pressure operations up to

2.5 MPa at lower temperatures, with pressure decreasing as temperature

increases, ensuring safety across various reaction conditions. Safety valves

and pressure transmitters are pre-installed to ensure secure operation, while a

KF25 vacuum port enables integration with vacuum or inert gas systems for

oxygen-sensitive reactions.

Designed for versatility, safety, and

repeatability, the KS-MFT-FB1200-3Z provides researchers with a reliable tool

for exploring advanced catalytic reaction mechanisms, reactor engineering, and

catalyst performance evaluation. It is ideal for use in chemical engineering

departments, energy research labs, and pilot-scale process development.

With its specialized design and

excellent thermal management, Luoyang Kunsheng Instrument Equipment Co., Ltd

delivers a highly functional and research-grade furnace system that meets the

demanding requirements of methane reforming, syngas production, and Fischer-Tropsch

synthesis.

Technical parameters:

| Model | KS-MFT-FB1200-3Z |

| Voltage | 308V AC, 50/60Hz, Three-phases |

| Power | 10 KW |

| Heating Furnace Design | Vertical split door for easy installation |

| Temperature Zones | Three zones with independent control |

| Total Heating Length | 900 mm (300 + 300 + 300 mm) |

| Max. Working Temperature | 1200°C (less than 30 mins) |

| Continuous Working Temperature | 1100°C |

| Recommended Heating Rate | ≤ 10°C/min |

| Temperature Controller | Three digital controllers for each zone |

| Controller Accuracy | ±1°C (optional Eurotherm 3000 with±0.1°C) |

| Programming Segments | 50 segments for heating, cooling, dwell |

| Control Features | PID Auto-Tune, over-temp & thermocouple failure protection |

| Gas Pre-heating Furnace Power | 2.4 KW |

| Gas Furnace Voltage | 208-240V AC, 50Hz |

| Gas Heating Zone Length | 400 mm |

| Gas Max Temperature | 700°C (≤ 2.5 MPa) |

| Gas Heating Tube Size | Ø 25 × 700 mm (spiral) |

| Quartz Tube | Ø 60 O.D. × Ø 52 I.D. × 1400 mm |

| Quartz Tube Feature | Frits with convection design + mechanical gauge |

| Alloy Tube | Ø 60 O.D. × Ø 50 I.D. × 1400 mm (Nickel base, CF60 flange) |

| Alloy Tube Feature | Pressure transmitter + mesh air distribution plate |

| Pressure @ ≤800°C | ≤ 2.5 MPa |

| Pressure @ ≤900°C | ≤ 2 MPa |

| Pressure @ ≤1000°C | ≤ 1.5 MPa |

| Pressure @ ≤1100°C | ≤ 1 MPa |

| Safety Valve | Auto-release when pressure exceeds range |

| Vacuum Port | KF25 port at bottom flange |

| Vacuum Pump | Not included (optional order) |