Product Description:

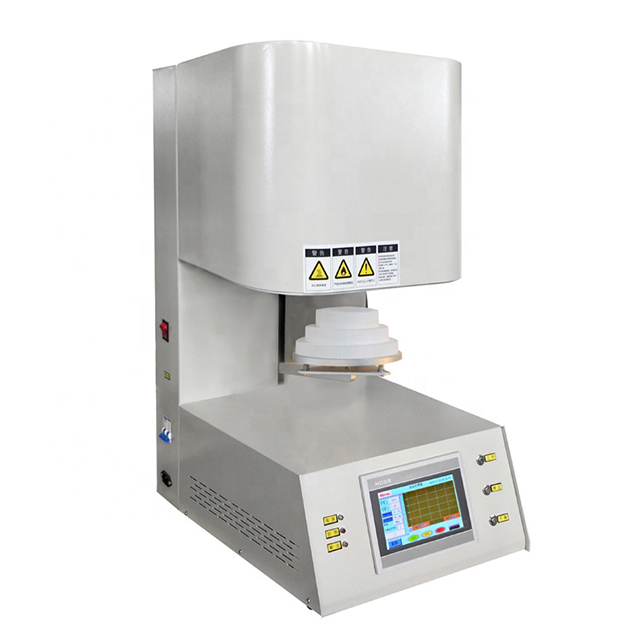

The KS-MFT-BL1700 is a high-performance

bottom loading muffle furnace developed by Luoyang Kunsheng Instrument

Equipment Co., Ltd, designed for demanding applications requiring precise and

stable high-temperature processing. With its advanced vertical-lift structure,

this furnace is ideal for laboratories, universities, and industrial users

engaged in material development, sintering, and heat treatment research.

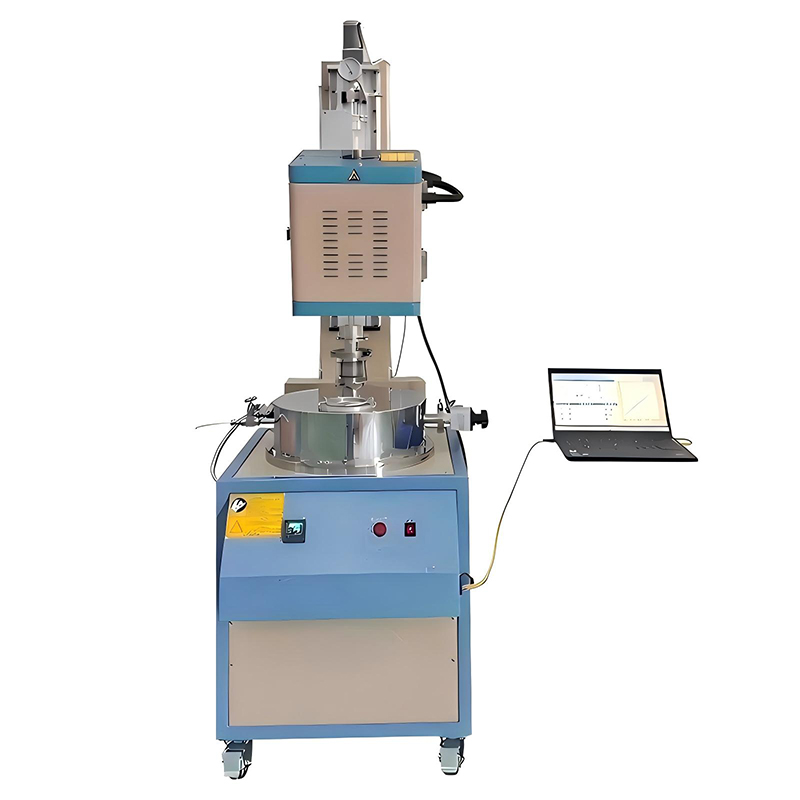

The bottom loading mechanism offers a

distinct ergonomic advantage, allowing users to safely load and unload heavy or

delicate samples from below without disturbing the heated zone. This design

significantly reduces heat loss during operation and minimizes the risk of

contamination, making it particularly suitable for repeated thermal cycles and

high-purity processing environments.

Constructed with a durable double-layer

steel shell and insulated using high-grade alumina fiber boards, the

KS-MFT-BL1700 delivers outstanding thermal efficiency while maintaining low

surface temperatures for safe operation. The uniform temperature field inside

the chamber ensures repeatable results across a range of advanced applications

such as ceramic sintering, powder metallurgy, material annealing, and crystal

growth.

The furnace is equipped with a

user-friendly PID temperature controller that supports complex heating

programs, including multi-step ramp and dwell profiles. With up to 30

programmable segments, users can configure highly specific thermal cycles to

suit their experimental or production requirements. Safety functions such as

over-temperature cutoff and thermocouple break protection are integrated by

default to ensure secure long-term operation.

Luoyang Kunsheng Instrument Equipment

Co., Ltd offers a variety of optional upgrades for this model, including

touchscreen controllers, digital data recorders, remote monitoring systems,

mixed-gas inlet ports, and high-vacuum compatibility. These customizable

features extend the furnace’s capability for atmosphere-controlled processes,

such as working under inert gas, oxygen detection, or even hydrogen safety

protection if required.

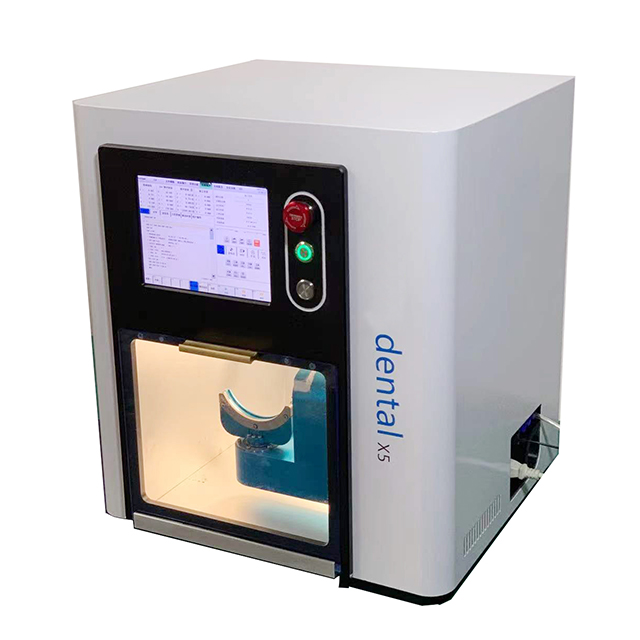

Designed with both performance and

usability in mind, the KS-MFT-BL1700 features a compact footprint, quiet

operation, and clean exterior aesthetics. The control interface is intuitive

and highly responsive, making it accessible for both experienced researchers

and first-time users.

Backed by our technical expertise and a

commitment to quality, this furnace offers not only high-temperature

functionality but also long-term durability and technical support. Whether for

research laboratories, pilot production lines, or quality control environments,

the KS-MFT-BL1700 is a dependable choice for precision heat treatment at

temperatures up to 1700°C.

Technical Parameters:

| Model | KS-MFT-BL1700 |

| Furnace Shell Structure | Double-layer carbon steel plate shell, surface sprayed with heat resistant plastic powder coating to ensure that the outer surface temperature of the furnace is ≤40°C |

| Chamber Materials | High-grade alumina fiber ceramic board and thermal insulation cotton |

| Furnace Door | Bottom loading door |

| Max. Temperature | 1700°C |

| Continuous Working Temperature | 1600°C |

| Heating Element | MoSi2 rod |

| Thermocouple Type | B type |

| Rated Voltage & Power | AC 110V/220V/380V/415V 50/60Hz; Power depends on chamber size |

| Chamber Size | 300×200×200 mm |

| Heating Rate | 0–30°C/min, suggest to use 1–2.2°C/min above 1600°C |

| Temperature Precision | ±1°C |

| Temperature Controller | Temp. Controller with 1 program storage capacity and 30 segments ramp & dwell; PID automatic control and auto-tune function. Built-in protection for over-heating and broken thermocouple |

| Optional Parts | Touch screen controller, paperless recorder, remote communication control system, 2–4 gas mixing system, higher vacuum optional, oxygen content detection, H₂ safety device |

| Warranty | One-year limited warranty with lifetime support, excluding heating element, cooling fans, thermocouple, and ceramic tube damaged by user. Damage caused by corrosive or acidic gases, or incorrect operation, is not covered under the warranty |