KS-VF-M2 Fusion Machine for Refractory Materials – Precision, Efficiency, and Reliability for XRF Sample Preparation

The KS-VF-M2 fusion machine is a high-performance solution designed specifically for the preparation of samples for X-ray fluorescence (XRF) analysis, with a strong focus on applications in the refractory materials industry. With increasing demands for accuracy and repeatability in elemental analysis, the KS-VF-M2 is engineered to deliver consistent, homogenous glass beads from metal blocks or powder samples, ensuring superior analytical results.

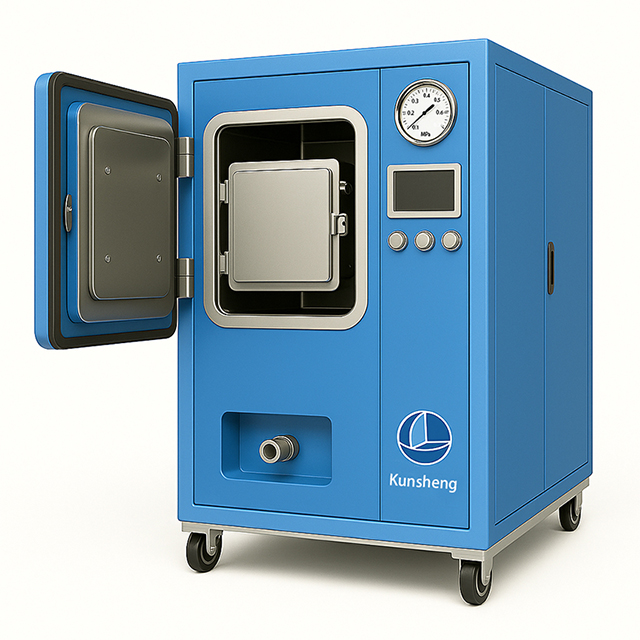

Developed by Luoyang Kunsheng Instrument Equipment Co., Ltd., the KS-VF-M2 reflects years of technical expertise and understanding of the needs of laboratories dealing with high-temperature and chemically aggressive materials such as iron-based, nickel-based, and copper-based samples. It is ideally suited for use in steel plants, cement manufacturers, mining operations, and research institutions where precise chemical composition plays a critical role in process control and product quality.

The machine operates under either vacuum or inert gas atmosphere, which is crucial for preventing oxidation or contamination during the melting process. This ensures that sensitive and reactive elements within the sample remain stable and accurately represented in the final analysis. Additionally, the system incorporates a dual-head design that allows for simultaneous or sequential fusion of two samples, enhancing throughput and operational efficiency in busy laboratory environments.

What sets the KS-VF-M2 apart is its user-friendly interface powered by a touch screen and programmable logic controller (PLC). All fusion parameters—such as heating time, power level, crucible rotation, swing angle, vacuum control, and protective gas filling—can be precisely set and automatically managed. This level of automation minimizes human error and enables reproducible sample preparation, which is vital for standardized testing protocols.

In practical use, the KS-VF-M2 has proven to be especially beneficial in the field of refractory materials, where sample composition can be complex and difficult to handle. The unit is compatible with various types of crucibles, including alumina, graphite, and platinum, making it flexible for different application requirements. The use of a swing-and-rotate mechanism further enhances the homogeneity of the melt by promoting uniform heat distribution and mixing, which is essential for producing defect-free glass beads suitable for XRF analysis.

The built-in safety features and robust stainless steel construction make the KS-VF-M2 a reliable partner in any laboratory. From its pneumatic locking furnace door to its automatic gas purging system and real-time pressure monitoring, every element has been designed with precision and operator safety in mind. Moreover, its compact design and quiet operation make it suitable for placement in a variety of lab settings without requiring specialized infrastructure.

Whether used in production quality control or in R&D laboratories, the KS-VF-M2 provides a critical link in the analytical chain—ensuring that samples are properly prepared for accurate, repeatable, and high-quality XRF results. By transforming challenging refractory materials into consistent, high-quality fused beads, it empowers analysts to unlock the full potential of their spectrometric equipment and meet today’s industry standards with confidence.

Technical Parameters:

| Product Model | KS-VF-M2 fusion melting furnace/machine |

| Crucible Capacity | 50–200g |

| Melting Method | Dual-head with rotation, swing, and casting |

| Atmosphere | Vacuum or inert gas |

| Temperature Control | Infrared sensor |

| Crucible Swing Angle | 0–90° adjustable |

| Swing Speed | 0–20 rpm adjustable |

| Crucible Rotation Speed | 0–20 rpm |

| Max Vacuum | 100 Pa (cold state) |

| Working Temperature | 0–1700°C |

| Vacuum System | VRD-8 direct pump + vacuum valves |

| Gas Control | Pressure sensor and CKD valves, auto fill/purge |

| Furnace Door | Motorized lift, pneumatic lock |

| Power Supply | 20 kW, 3-phase 380V, 50Hz |

| Dimensions | 1100×550×1250 mm (L×W×H) |

| Weight | ~150 kg |

| Chamber Material | Stainless steel, matte finish |