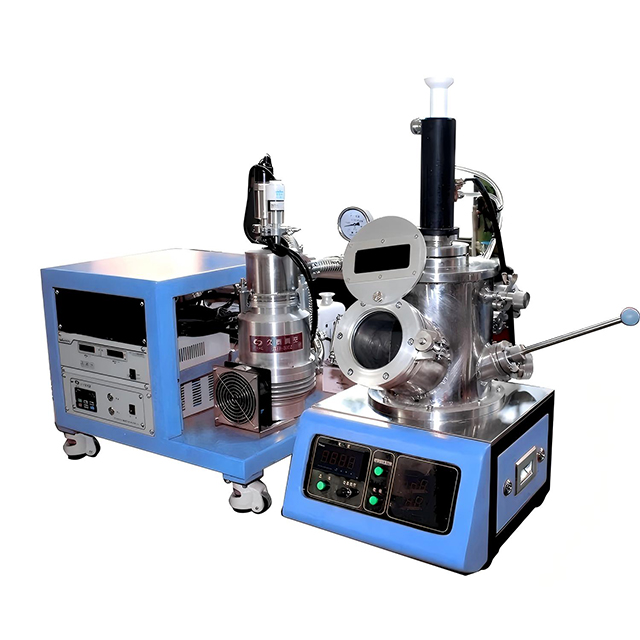

Product Description:

SPS fast pressure sintering system is one of the most advanced fast hot press sintering systems in the world, characterized by the fast sintering speed and high density sintering. It is the most powerful tool used to sinter the nanophase material, gradient functional material, mesoporous nanoscale thermoelectric material, rare earth permanent magnetic material, alloy glass nonequilibrium material and biological material.

Spark Plasma Sintering (SPS) is a new technology for rapid consolidation of powders. SPS uses a strong current pulse power supply to stimulate and promote the consolidation and reaction sintering process of materials. Compared with traditional technologies, during the processing of SPS, the density of various conductors, non-conductors and composite materials can be adjusted to any required value. SPS shortens the experimental time and energy consumption to the greatest extent, while perfectly maintaining the micro-nano structure of the material. Therefore, since its birth, it has quickly become an important tool in many fields such as scientific research, new material research and development, and industrial production.

The spark plasma sintering system has a maximum temperature of 2000℃. It can be used for material annealing, material hot pressing bonding, surface treatment and synthesis, etc. The processed samples can be metals, ceramics, nanomaterials and amorphous materials. This equipment is particularly suitable for the research of solid electrolytes and thermoelectric materials

Technical Parameters:

| Model | KS-SPS-Mini20T |

| Power | 20 KW |

| Input Voltage | AC 380V, 50Hz, 3-phase |

| Output Current | DCO-1500A (digitally controlled) |

| Output Voltage | DCO-10V (digitally controlled) |

| Pulse Width Range | 5–255 ms (adjustable) |

| Pulse Frequency Range | 2–1000 Hz (adjustable) |

| Max Temperature | 1600℃ (B-type thermocouple) |

| Die Diameter | 100 mm |

| Max Heating Rate | 300℃/min |

| Temperature Control System | Eurotherm controller, accuracy ±0.1℃ |

| Pressure Application | Manual hydraulic system |

| Max Pressure | 20 T |

| Vacuum Level | 10 Pa (7.5×10⁻² Torr, mechanical pump)1 Pa (1×10⁻⁴ Torr, molecular pump system optional) |

| Cooling System | Built-in water chiller, flow rate 58 L/min |

| Mold Size Range | 12–50 mm (customizable) |

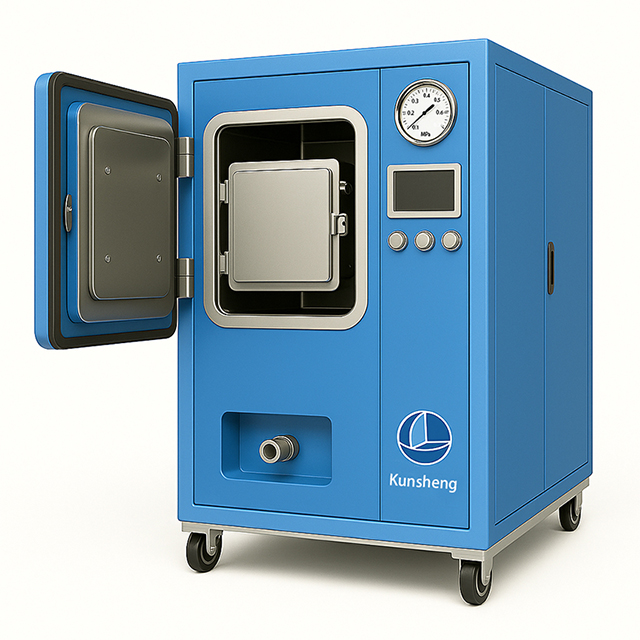

| External Dimensions | Power Unit 760 × 460 × 1820 m mFurnace Body 970 × 720 × 1400 mm |