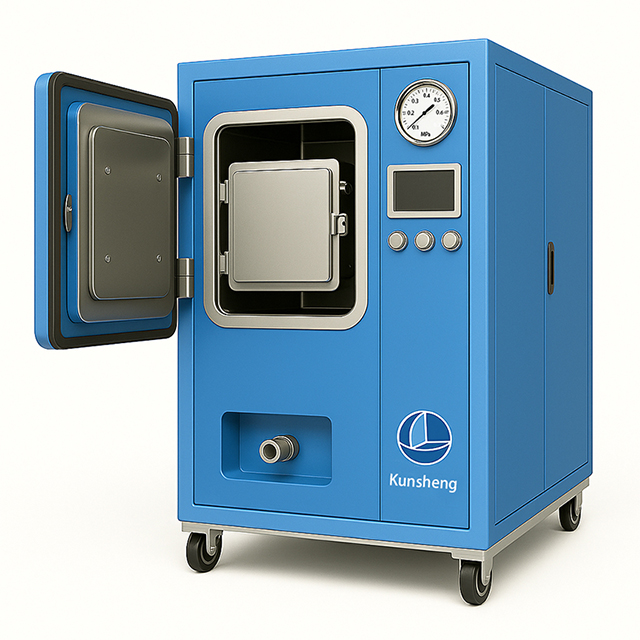

Product Description – KS-VF-CCF2 Vacuum

Continuous Casting Machine

The KS-VF-CCF2 is a next-generation

vacuum continuous casting machine specifically designed for precious metal

processing. Engineered with precision, reliability, and safety in mind, this

equipment serves a wide range of applications in jewelry manufacturing, metal

refining, research institutions, and custom alloy production.

This machine allows users to produce

high-quality metal castings with minimal oxidation and superior surface finish.

It supports multiple casting shapes such as flat plates, rods, and tubes,

making it an ideal solution for diversified production needs. Whether you’re

forming raw materials into standard bars or customizing shapes for downstream

processes, the KS-VF-CCF2 delivers consistent, repeatable results.

Built for ease of use, the equipment

features an ergonomic vertical structure that saves space and provides

intuitive access to controls and maintenance components. Its intelligent

interface and efficient thermal system enable users to complete casting cycles

quickly and safely, even under high-temperature environments.

Key Features

✔ Vacuum Casting Precision

Enables oxidation-free casting by isolating the molten metal from ambient air, preserving purity and preventing unwanted reactions during solidification.

✔ Versatile Mold Compatibility

Supports various casting mold types, allowing users to produce a wide range of shapes to suit different processing needs.

✔ Inert Gas Operation

Capable of operating under protective gas environments such as argon or nitrogen, ensuring better quality output and reducing the risk of oxidation.

✔ Fast and Efficient Workflow

Engineered for rapid heating and short turnaround times, this machine boosts productivity without compromising on casting quality.

✔ Intuitive Control Interface

Equipped with a streamlined panel that simplifies machine operation and status monitoring, making it suitable even for first-time users.

✔ Compact, Space-Saving Design

The vertical structure not only minimizes floor space requirements but also enhances access for routine inspection and maintenance.

Advanced Safety Protection

The KS-VF-CCF2 includes six integrated safety systems designed to minimize risk and protect both the operator and the equipment:

Overcurrent Protection – Prevents electrical overloads during operation.

Fault Alarm System – Provides real-time alerts in case of any malfunction.

Water-Electric Isolation – Ensures safer operation by separating the cooling and electrical systems.

Overvoltage Protection – Guards against sudden power surges or instability.

Temperature Safety Shutdown – Automatically stops operation if temperatures exceed safe levels.

Short Circuit Protection – Instantly halts the system in case of a short circuit to prevent further damage.

Technical Parameters:

| Model | KS-VF-CCF2 |

| Power | 15 kW |

| Voltage | 380V, 3 Phase |

| Maximum Temperature | 1600℃ |

| Thermocouple Type | Type R, 1600℃ |

| Maximum Capacity | 2 kg (Gold) |

| Casting Shapes | Plate, Round Rod, Square Rod, Tube |

| Working Gas | Argon, Nitrogen |

| Applicable Metals | Gold, K Gold, Silver, Copper and Their Alloys |

| Melting Time | 10 minutes |

| Dimensions | 900 × 1150 × 2000 mm |

| Weight | 260 kg |