Product Description:

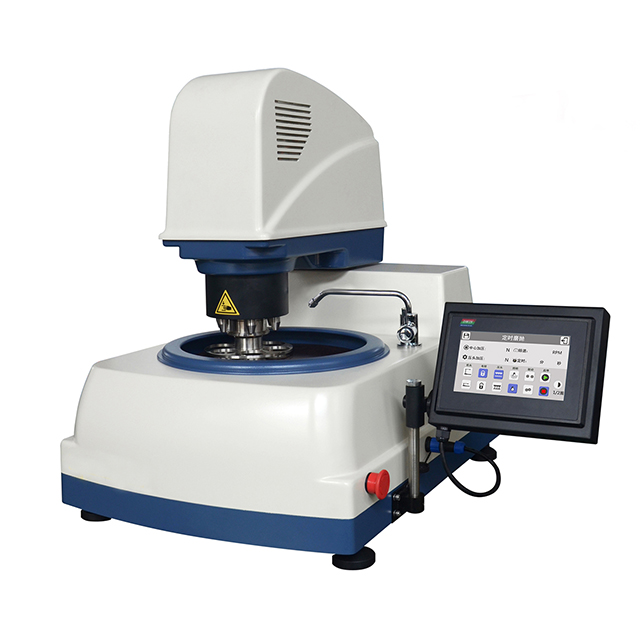

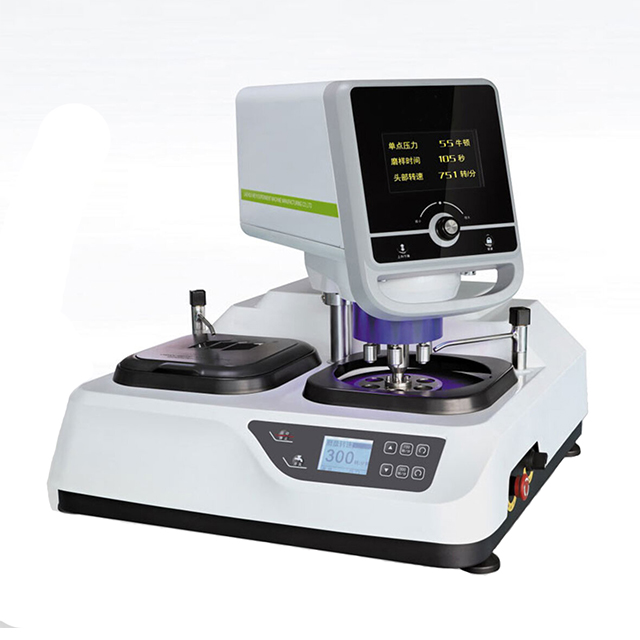

The KS-GPM-1S is a state-of-the-art

horizontal planetary ball mill designed to deliver exceptional performance in

fine grinding, mixing, homogenizing, and mechanical alloying of a wide range of

materials. Built with robust engineering and advanced digital control, this

compact table-top machine is ideal for use in laboratories, research

institutions, and small-scale industrial applications requiring reliable and

efficient milling.

The KS-GPM-1S features a horizontal

design with four grinding stations, offering enhanced centrifugal force and

improved milling uniformity compared to traditional vertical planetary mills.

The horizontal structure ensures more stable rotation and minimizes vibrations,

resulting in greater grinding precision and reproducibility. It also reduces

wear on the jars and balls, extending the life of consumables while maintaining

high milling efficiency.

Equipped with a large color touch screen

controller, this mill allows users to program multi-step speed cycles with

individual segment durations, speed profiles, and rotation direction controls.

Up to 10 unique recipes can be stored, each containing up to 5 programmable

segments. The rotation direction can be automatically alternated between

clockwise and counterclockwise, which ensures uniform particle size

distribution and prevents material layering or sedimentation. Each segment can

be set up for a maximum duration of 99 hours, 59 minutes, and 59 seconds,

making the system ideal for extended grinding cycles.

The revolution speed of the main disc is

adjustable from 0 to 400 RPM, while the jars themselves can self-rotate up to

800 RPM. This dual-motion system generates powerful centrifugal acceleration,

reaching up to 34 g, which significantly enhances the pulverizing effect. As a

result, the KS-GPM-1S can achieve remarkable fineness: wet milling allows for

particle sizes below 1 μm, and dry milling can produce sizes under 20 μm,

depending on the sample’s characteristics and milling conditions.

The system is compatible with a variety

of milling jars including stainless steel, vacuum-sealed stainless steel,

tungsten carbide (WC), alumina, and zirconia (ZrO₂). Special 4-cavity stainless

steel jars are also available, allowing simultaneous processing of up to 16

samples for high-throughput applications. The unit includes four holding

fixtures, each capable of securing jars up to 80 mm in height, ensuring reliable

and vibration-free operation.

The machine accepts a feed size of up to

10 mm for brittle materials and 3 mm for harder or irregularly shaped samples.

This versatility makes the KS-GPM-1S suitable for a wide array of sample types

including ceramics, composites, ores, metal powders, pharmaceuticals, and more.

Operating on a standard 208–240V AC

single-phase supply (50/60 Hz), the KS-GPM-1S is energy-efficient with a rated

power consumption of only 550W. For users operating on 110V power, an optional

>1000W transformer is recommended. The compact footprint and low noise level

(55–70 dB) make this instrument suitable for benchtop operation in virtually

any laboratory setting.

Engineered with safety and durability in

mind, the system incorporates multiple fail-safes, temperature resistance

features, and sound insulation. Its intuitive user interface, precise control,

and consistent performance make it a trusted tool for researchers focused on

advanced material processing and development.

The KS-GPM-1S comes with a one-year

limited warranty and lifetime technical support. Please note that consumable

parts, such as milling jars and balls, are not covered under warranty.

Whether you're working in academic

research, materials development, or quality control, the KS-GPM-1S horizontal

planetary ball mill delivers dependable performance and advanced control for

your most demanding grinding applications.

Technical parameters:

| Model | KS-GPM-1S |

| Working Voltage | 208 - 240V AC (single-phase), 50/60 Hz |

| Max. Power Consumption | 550W |

| Rotary Speed | 0~400 RPM (Revolution), 0~800 RPM (Self-rotation) |

| Centrifugal Acceleration | Max 34 g |

| Speed Ratio | Revolution Self-rotation = 1/2 |

| Touch Screen | Digital display, recipe storage up to 10, up to 5 speed segments per recipe |

| Max. Segment Time | 99 hours 59 minutes 59 seconds |

| Rotation Direction | Clockwise and Anticlockwise selectable |

| Material Feed Size | <10mm (Crispy materials), <3mm (Others) |

| Material Output Size | <1μm (Wet milling), <20μm (Dry milling) |

| Noise Level | 55~70 decibel |

| Holding Fixtures | 4 sets included, jar height up to 80mm |

| Compatible Milling Jars | 100ml SS, SS Vacuum, WC, Alumina, ZrO2, 4-cavity SS, etc. |

| Warranty | One-year limited with lifetime support |