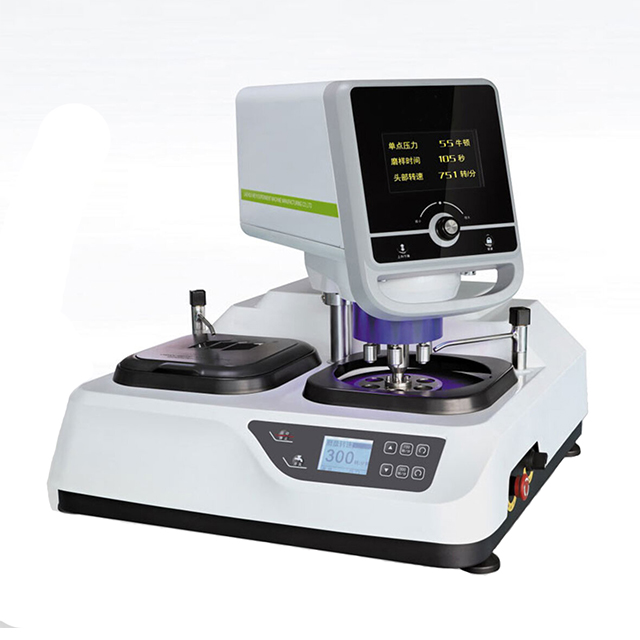

Product Description:

The KS-GPM-8 is a precision-engineered

agate grinding mill designed to meet the demanding needs of modern laboratories

in materials science, chemistry, electronics, and environmental research. With

a compact form factor and advanced automation features, this mill is ideal for

researchers seeking high-efficiency, low-contamination grinding in controlled

environments.

The heart of the KS-GPM-8 lies in its

robust construction and the use of natural agate as the grinding material.

Agate is widely appreciated in scientific applications for its high hardness,

excellent chemical resistance, and non-metallic properties, making it the ideal

medium for processing sensitive samples such as semiconductors, minerals,

biological tissues, rare-earth materials, or high-purity powders. Unlike metal

or ceramic grinding vessels, agate minimizes sample contamination and preserves

the original chemical composition of specimens.

This model is specifically designed for

precision grinding tasks where consistency, repeatability, and purity are

critical. It employs an automatic rotating mechanism that enables both the

mortar and pestle to work together harmoniously to achieve fine and uniform

particle sizes. The pressure applied during grinding is carefully regulated

using an internal spring system, which reduces operator intervention and

increases reproducibility across multiple runs.

KS-GPM-8 features a compact vertical

design that conserves bench space while maintaining excellent operational

stability. Its modern appearance is complemented by intuitive operation,

suitable for both experienced researchers and laboratory technicians. The

machine operates with very low vibration and noise, which enhances user comfort

and allows integration into cleanrooms or gloveboxes. In fact, the grinder’s

enclosure-friendly dimensions and modular structure enable it to be placed

inside a glove box via an airlock, making it suitable for working with

air-sensitive or hazardous materials under inert gas environments.

One of the key advantages of the

KS-GPM-8 is its user-centric design. Every aspect—from the grinding bowl’s

geometry to the spatula included for improved mixing—has been optimized for

laboratory efficiency. The agate bowl and pestle are easy to disassemble and

clean, reducing downtime between sample runs and preventing

cross-contamination. The supplied spatula is designed to evenly distribute

materials during grinding, ensuring a more uniform mixture and preventing

sample build-up along the bowl walls.

This grinder supports dual-speed

adjustment for the mortar and pestle, providing flexible control over the

grinding action. The pestle rotation can be finely tuned to suit different

materials and sample types, whether delicate or hard. This flexibility makes

the KS-GPM-8 well-suited for both soft organic samples and brittle crystalline

solids, accommodating a wide range of research and development workflows.

In addition to its performance and

design advantages, the KS-GPM-8 is backed by a reliable support program,

including a two-year limited warranty and lifetime technical assistance. This

ensures that users not only receive a reliable piece of laboratory equipment

but also ongoing support throughout the instrument’s service life.

Safety is another priority in the

KS-GPM-8. The enclosed grinding chamber prevents material spillage and reduces

exposure to fine particulates, which is particularly important when working

with toxic or nanomaterial samples. The electronic system is protected with a

universal power adapter and internal voltage regulation, ensuring consistent

performance regardless of the regional power standard.

In summary, the KS-GPM-8 agate grinding

mill represents a sophisticated solution for sample preparation in

high-precision applications. Its use of agate components for grinding, combined

with automation, safety, and inert-atmosphere compatibility, makes it an

indispensable tool for laboratories focused on purity, reproducibility, and

efficient sample processing. Whether used in academic research, industrial

development, or environmental analysis, this model is built to deliver results

with confidence and consistency.

Technical Parameters:

| Model | KS-GPM-8 |

| Working Voltage | 110-240V AC via 24V DC power adapter |

| Max. Power Consumption | 150W |

| Grinding Bowl | Inner diameter is 130mm |

| Plastic Spatula | Designed for spreading the substance in the grinding bowl to improve mixing |

| Grinding Speed (Mortar) | 0 - 10rpm |

| Grinding Speed (Pestle) | 0 - 90rpm adjustable |

| Grinding Pressure | Adjustable by spring |

| Dimension | 240mm(L) x 240mm(W) x 500mm(H) or 9.4" x 9.4" x 19.7" |

| Net Weight | 38 lbs |

| Warranty | Two-year limited warranty with lifetime technical support |

| Application Note | Please crush bulk sample before grinding using our electric Jaw crusher. This compact automatic grinder can be put into a glove box via airlock port and operate under inert gas. |