Product

Introduction

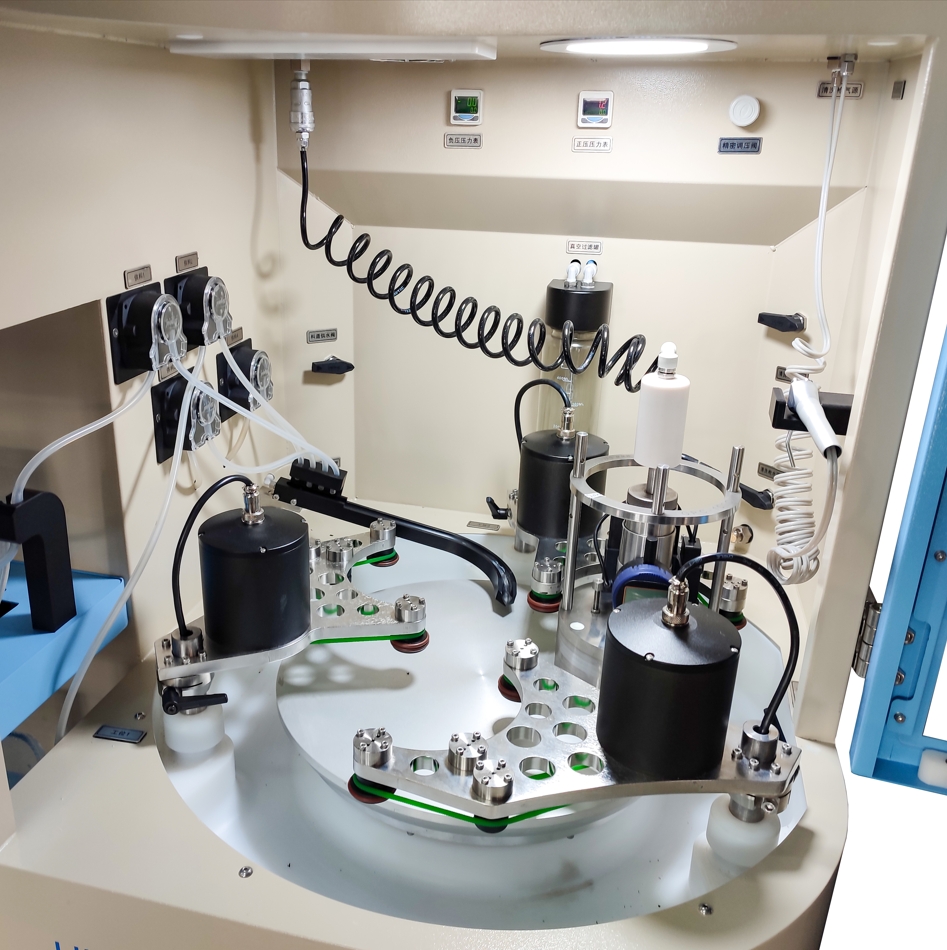

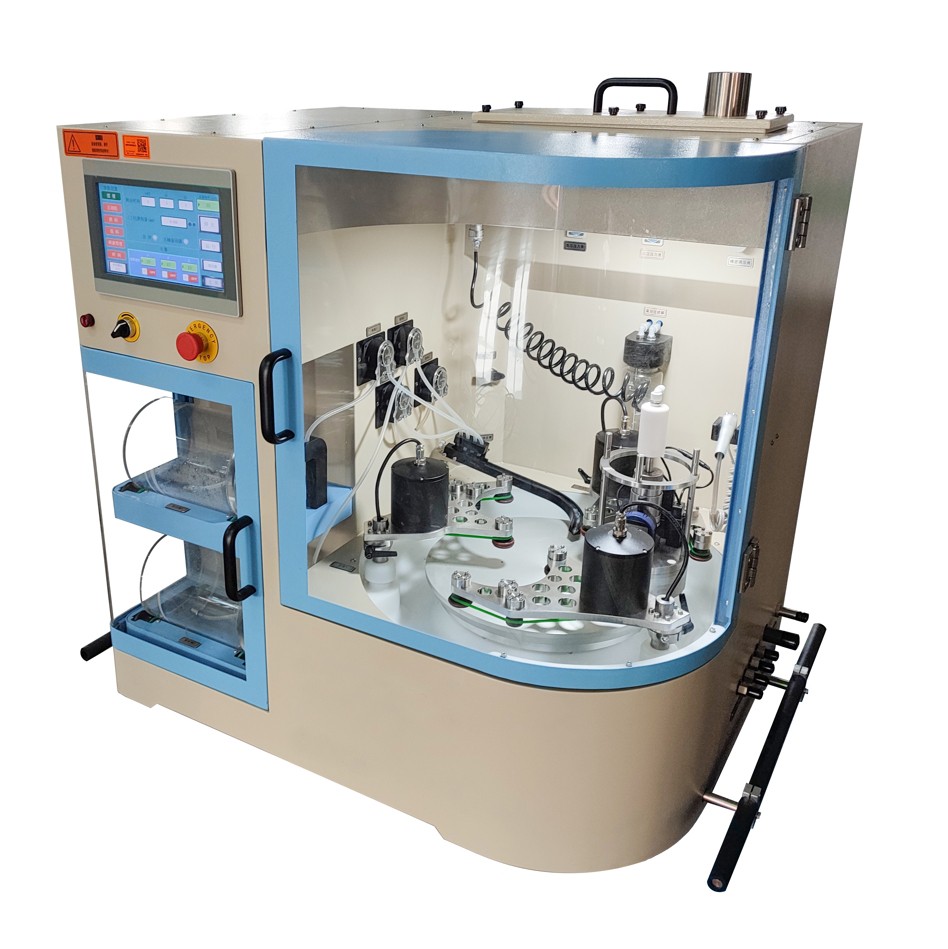

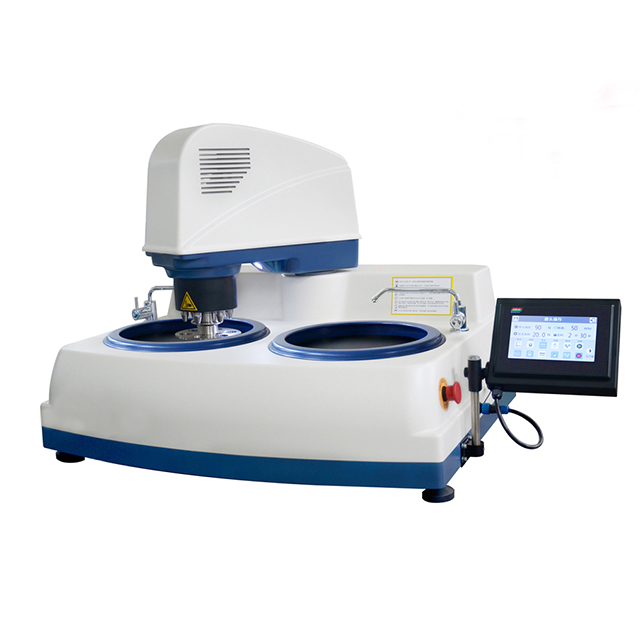

The KS-GPM-1503

Precision Automatic Grinding and Polishing Machine is a high-performance

system designed with three independent working positions, offering flexible and

efficient sample preparation for various materials. It is especially suitable

for large-sized or irregularly shaped samples requiring flat surface grinding

and polishing. Typical applications include ceramics, metals, glass, rocks,

minerals, PCB boards, infrared optical crystals (such as SiC, sapphire,

quartz), refractory materials, and composite samples.

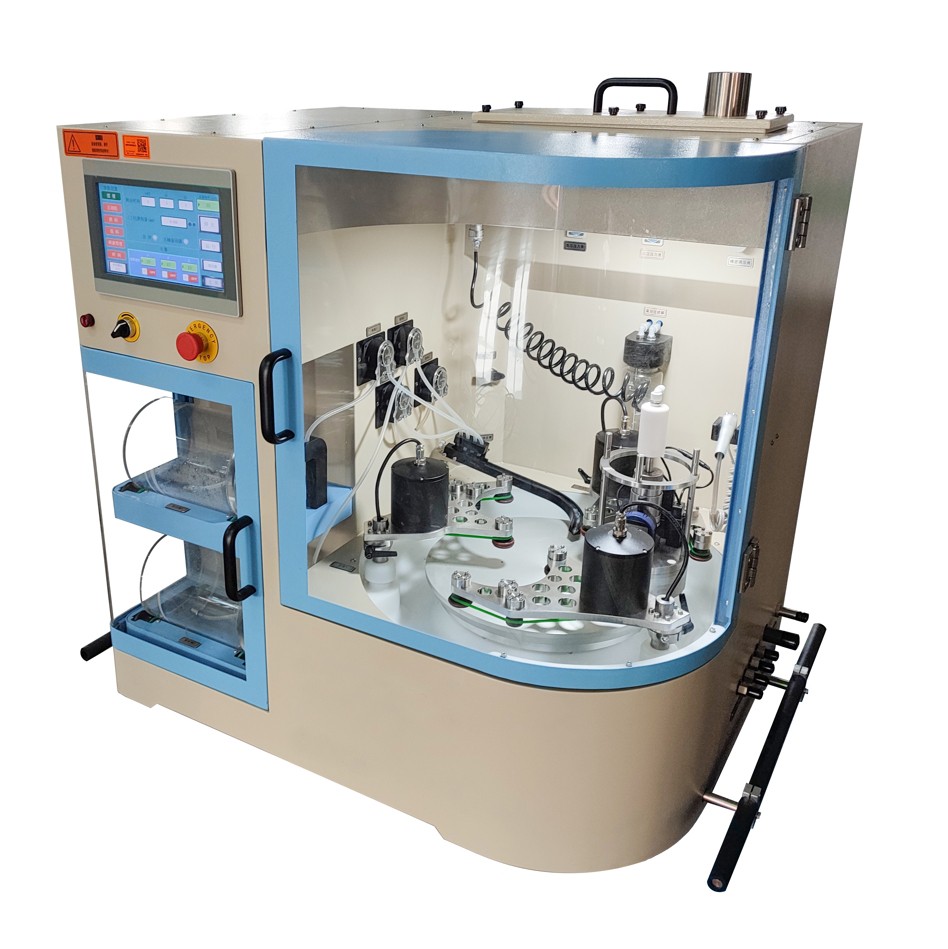

This

equipment is widely used in materials research, educational institutions,

quality inspection departments, and production labs. With three Φ381mm

precision grinding/polishing plates and a high-efficiency circulation

filtration system, it enables precise, stable, and high-throughput sample

processing.

Product

Features

- Triple Workstation

Design:

Equipped with 3 independent grinding/polishing heads, enabling

simultaneous or batch processing of multiple samples, improving

productivity.

- Large-Diameter Discs: 381mm grinding plates

offer excellent coverage for large or multiple samples, increasing surface

uniformity and efficiency.

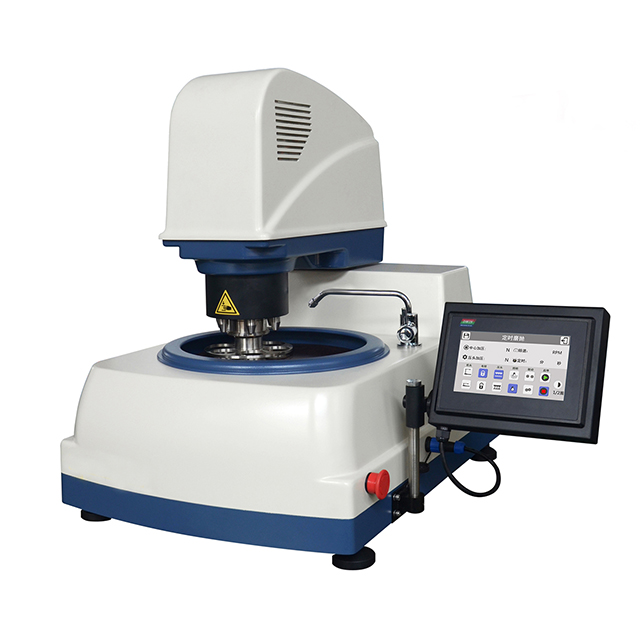

- Automatic Pressure

Control:

The blue polishing head applies consistent pressure, adjustable by

software, ideal for fixed-thickness or precision polishing tasks.

- Flexible Motion Options: Programmable

vibration, rotation, and lift controls support diverse processing

workflows, customizable to your polishing needs.

- Advanced Control System: Integrated 10”

touchscreen with intuitive UI allows easy adjustment of all parameters,

storing multiple user-defined programs.

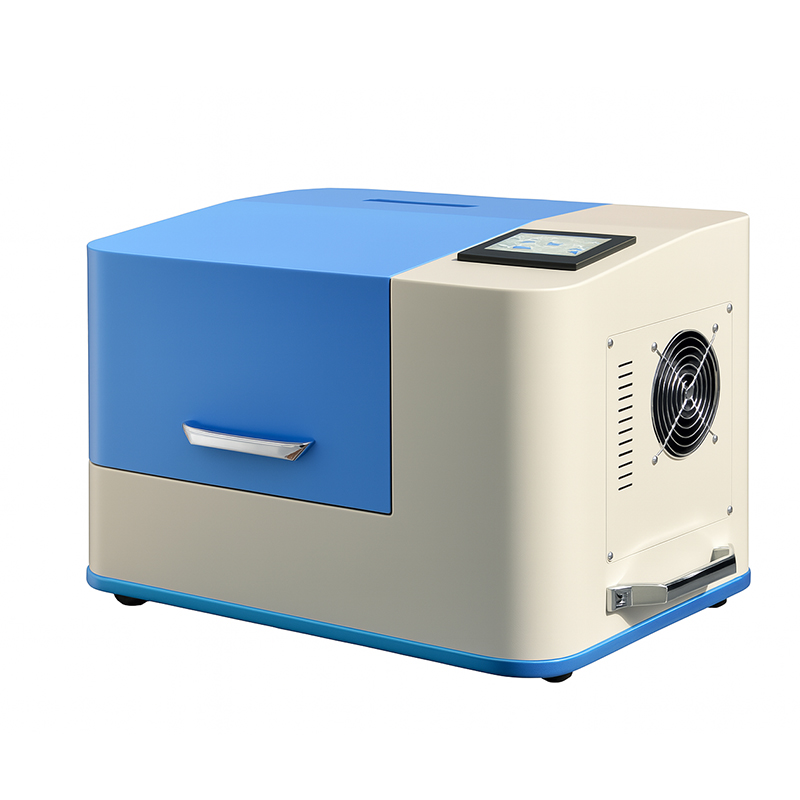

- Clean and Efficient: Built-in

high-efficiency filtration and drainage system keeps the workspace clean

and reduces maintenance.

- Safe and Reliable: Multiple protection

features including time-based limits and magnetic sensors to prevent

overtravel or motor damage.

- Optional Add-ons: Gas interface, sample

fixture customization, and dual-mode polishing options available upon

request.

Main specification:

| Product Model | KS-GPM-1503 |

| Power Supply Interface | AC220V 50Hz 10A |

| Grinding Head Drive Motor (Main) | AC servo motor |

| Grinding Plate Speed | 10–120 rpm |

| Grinding Plate Rotation Mode | Single direction, reversible rotation |

| Grinding Plate Quantity | 3 plates, each Φ381mm |

| Sample Holder Tray | Flat rotary tray ×1, diameter Φ110mm |

| Grinding Plate Tray | Flat tray or maintenance tray ×2, diameter Φ143mm |

| Maximum Sample Size | 4" |

| Polishing Working Stations | 3 |

| Polishing Head Drive | DC brushless motor |

| Polishing Head Vibration Mode | Position-controlled 3–10 steps, MAX vibration frequency ≈10 times/min |

| Polishing Head Lifting Mode | Stepper motor |

| Main Shaft Speed Range | 1–300 rpm adjustable |

| Blue Polishing Head Control Device (Mechanical) | Quantity 1 with optional Φ103mm sample tray (2 additional optional heads available) |

| Mixing & Polishing Working Stations | 2 |

| Mixing Speed Adjustable Range | 5–30 rpm |

| Mixing Power | 1.4 kW ×2 |

| Liquid Storage Tank Capacity | 500 mL ×2 |

| Liquid Supply Working Stations (Peristaltic Pump) | Total 4, including 1 liquid supply and 2 liquid delivery outlets |

| Droplet Dispense Speed | 0.1–20 rpm |

| Drainage System | High-efficiency filtration and recirculation |

| Grinding Head Lifting Limit | Time and magnetic field dual protection |

| Control System | Integrated touchscreen with 10" display |

| Optional Features | • Sample rotation, intelligent sensing, exhaust function, optional gas system• Blue polishing head interface can be customized with actual sample trays |

| Product Dimensions | • Main Unit1000mm × 800mm × 1050mm• Open Size 1650mm × 800mm × 1050mm |