Product Description:

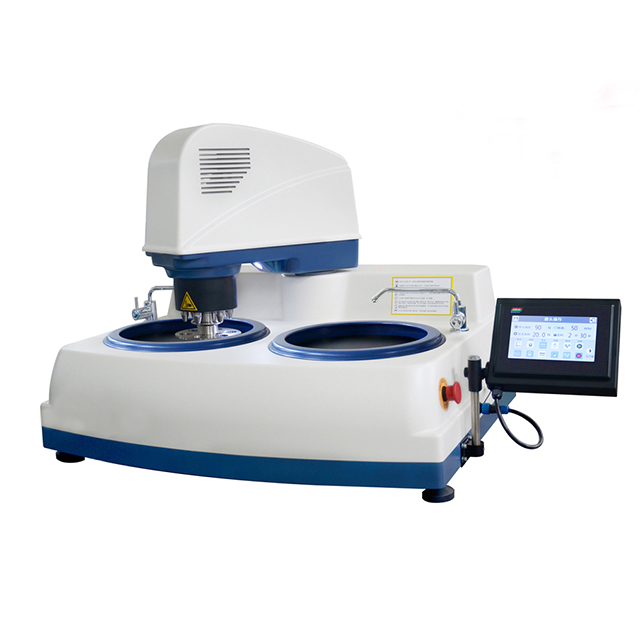

The KS-GPM-1210S is a fully automatic

pressure-controlled lapping and polishing system designed for precision surface

finishing of various hard and brittle materials. Developed with advanced

technology and user-centered design, this system is ideal for processing

materials such as metals, ceramics, glass, rock samples, and mineral specimens.

Its robust structure, automated operation, and high consistency make it

suitable not only for laboratory research but also for small-scale production

environments that require stable and repeatable results.

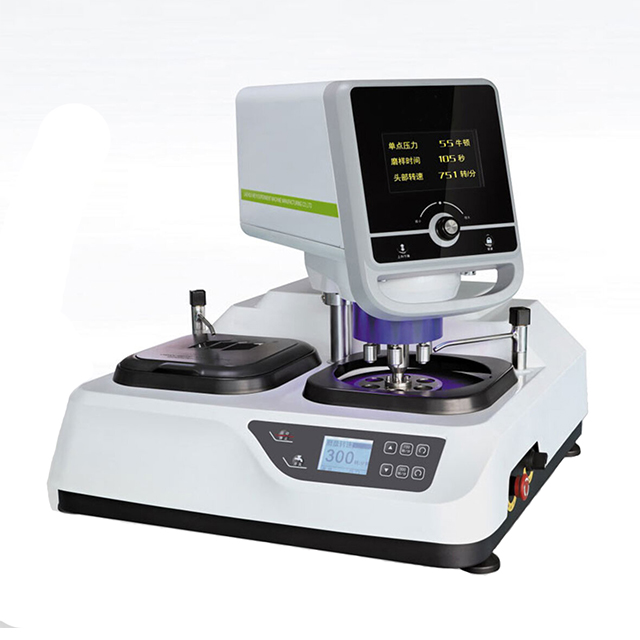

At the core of the KS-GPM-1210S is a

high-precision control system that enables fully automated processing cycles.

Operators can program lapping and polishing sequences to meet specific surface

finish requirements, minimizing the need for manual intervention. The

integration of automatic pressure control allows for uniform material removal

across all samples, resulting in flat, polished surfaces with minimal variation

between workpieces.

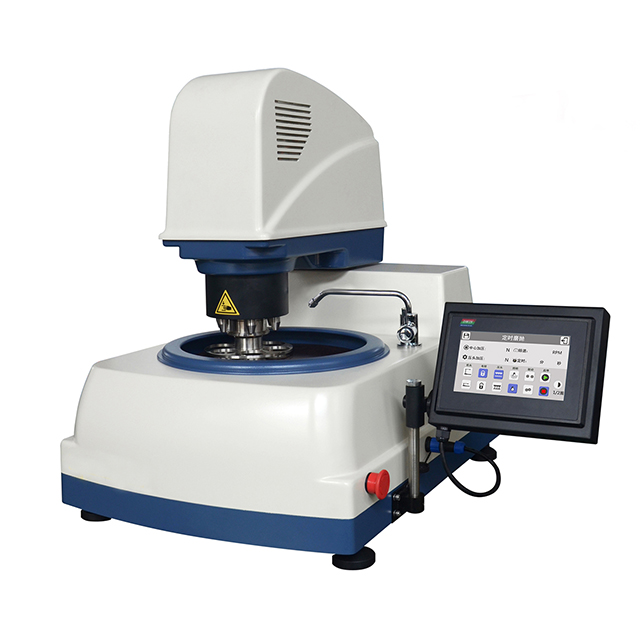

The machine is engineered for excellent

reliability and long-term durability. Its heavy-duty frame and high-quality

components ensure stable operation even during extended working hours. The use

of corrosion-resistant materials and an ergonomic layout enhances both

longevity and ease of maintenance. The intuitive control panel provides

real-time monitoring of process status, offering operators complete control and

flexibility over polishing parameters.

One of the key features of the

KS-GPM-1210S is its intelligent sample holder system, which accommodates

multiple specimens at once. This significantly boosts productivity by allowing

simultaneous processing of several samples under consistent pressure and

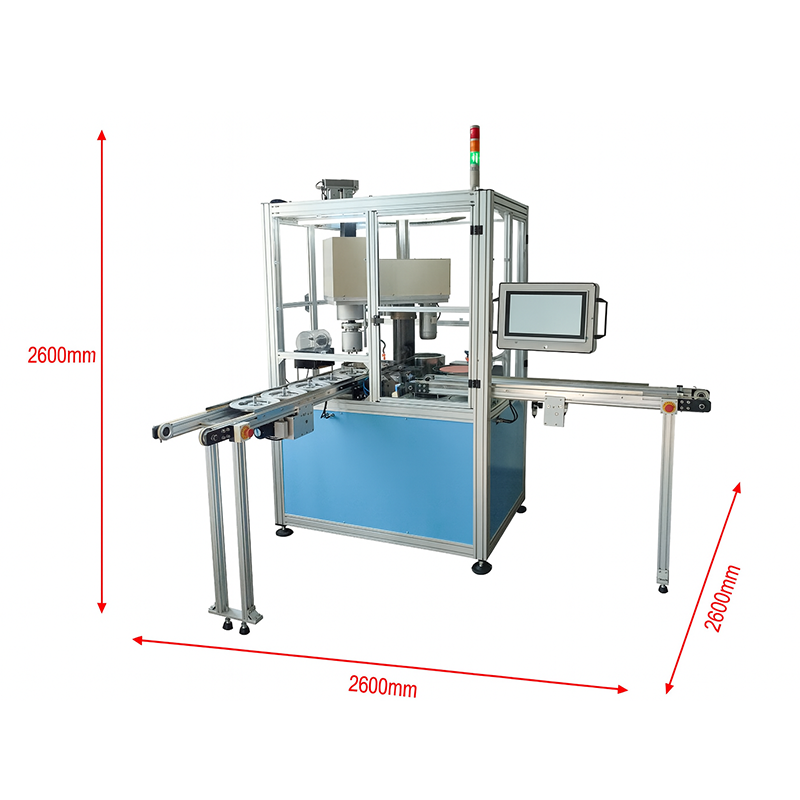

motion. The automated in/out conveyor system further streamlines the workflow

by enabling continuous loading and unloading of samples, thereby reducing

downtime and labor requirements.

Technical Parameters:

| Model | KS-GPM-1210S |

| Power Supply | 220V, 50Hz |

| Lapping Speed | 10–300 rpm |

| Polishing Speed | 10–300 rpm |

| Sample Holder | Φ160mm, up to 5 samples |

| Conveyor System | 1650×300mm in/out sample tray conveyor |

| Air Supply Pressure | 0.1–0.7 MPa |

| Pressure Spindle Speed | 10–100 rpm |

| Pressure Spindle Pressure Range | 0.1–30 kg |

| Water Supply | Water storage container (provided by the customer) |

| Dimensions | 2600mm × 2600mm × 2600mm |