Product

Description:

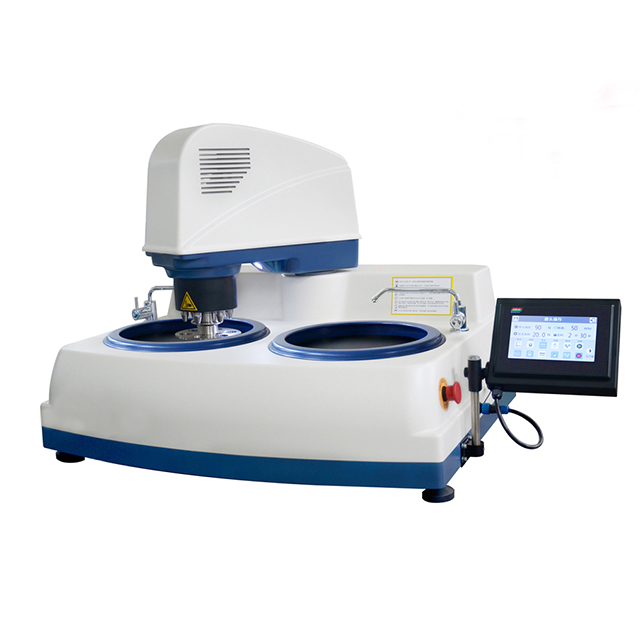

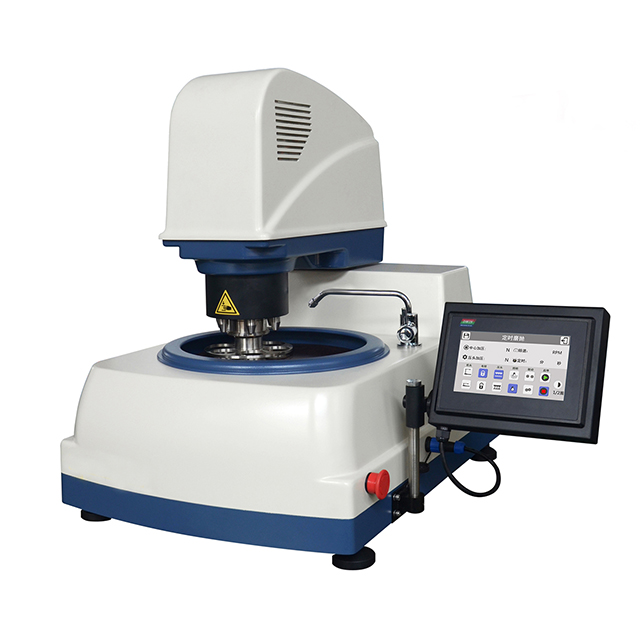

The KS-GPM-13S

Vertical Planetary Ball Mill is a high-efficiency, precision-engineered

grinding system designed for advanced laboratory-scale sample preparation.

Engineered with innovation and durability in mind, this benchtop device is

tailored to meet the diverse grinding, mixing, and homogenizing requirements

found in research institutions, materials labs, universities, and R&D

centers.

This

compact system is equipped with four grinding stations, each capable of

accommodating stainless steel jars with a 4-cavity design. This configuration

enables the simultaneous processing of up to 16 different samples per batch,

which greatly enhances productivity and allows for comparative sample analysis

under identical processing conditions. The jars are tightly secured using

robust holding fixtures that can accommodate vessels with heights of up to 80

mm, ensuring reliable operation even at high speeds.

At

the heart of the KS-GPM-13S is a powerful 550W motor operating on 208–240V AC,

50/60 Hz. It delivers exceptional centrifugal force and rotational energy,

providing the user with efficient grinding performance and excellent particle

size reduction. The main disk rotates at adjustable speeds up to 324 RPM, while

each jar experiences a self-rotation up to 648 RPM, enabling a unique planetary

motion. This 1:2 speed ratio ensures uniform grinding and fine control over

particle size and homogeneity.

The

system supports both wet and dry milling, with output granularity reaching sub-micron

levels, depending on the material's hardness, feed size, and media type. Wet

milling can achieve particles averaging below 1 μm, while dry milling typically

yields results below 20 μm. For specialized applications, the unit is capable

of producing powders as fine as 0.1 μm, depending on material properties and

duration of processing.

One

of the standout features of the KS-GPM-13S is its advanced touch-screen control

panel. This intuitive interface allows users to configure up to 10 stored

recipes, each with a maximum of 5 programmable speed segments and up to 10

cycles. Additional functions include direction control

(clockwise/anticlockwise), real-time speed monitoring, and precise time

adjustments—up to 99 hours 59 minutes per segment—making it suitable for both

short bursts and extended grinding procedures.

To

support material compatibility, the KS-GPM-13S is supplied with four sets of

stainless-steel milling jars and balls. The included jars are ideal for

metallic and hard inorganic materials, while optional jar materials (sold

separately) such as tungsten carbide, zirconia, alumina, nylon, and agate

enable contamination-free processing for sensitive applications like pharmaceuticals,

semiconductors, and nanomaterials.

The

vertical design minimizes the machine’s footprint while enhancing user

accessibility and stability. Its noise level ranges between 55 to 70 dB, making

it suitable for indoor laboratory environments without excessive disruption.

The unit is also engineered for easy maintenance and long-term operation, with

a sealed chamber that minimizes dust and contamination during milling.

Overall,

the KS-GPM-13S combines compact form, advanced control, and powerful grinding

performance into a versatile tool for modern material research. Whether you are

conducting alloying, chemical mixing, powder dispersion, or nanoparticle

synthesis, this vertical planetary ball mill delivers the flexibility and

precision required for reproducible and reliable results.

Technical

Parameters:

| Model | KS-GPM-13S |

| Voltage | 208–240V AC single-phase 50/60Hz |

| Power | 550W max |

| Revolution Speed | 30–324 RPM adjustable |

| Self-Rotation Speed | 60–648 RPM adjustable |

| Speed Ratio | 1/2 |

| Control Method | Touch screen digital control |

| Recipes Stored | Up to 10 |

| Speed Segments | Up to 5 segments per recipe |

| Cycle Count | Up to 10 cycles |

| Max Time per Segment | 99 hours 59 minutes 59 seconds |

| Rotation Direction | Clockwise and counterclockwise selectable |

| Material Feed Size | <10mm for crispy materials <3mm for others |

| Output Granularity (Wet) | <1 μm average |

| Output Granularity (Dry) | <20 μm average |

| Minimum Granularity | 0.1 μm possible |

| Milling Jars | 4 sets of 4-cavity SS jars included (10ml per cavity) |

| Milling Balls | 4 sets of SS milling balls included |

| Noise Level | 55–70 dB |

| Holding Fixtures | 4 sets included, max jar height 80mm |