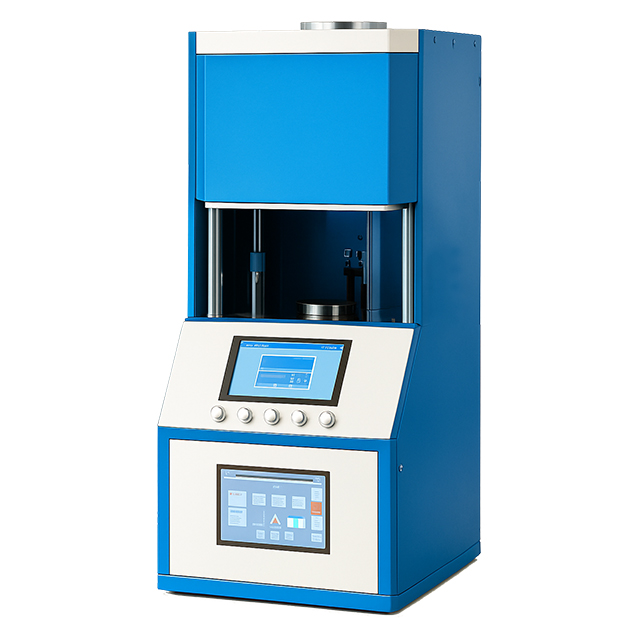

The KS-CIP-60J Cold Isostatic Pressing Machine is a robust and precision-engineered system designed to meet the high-pressure forming needs of ceramics, powder metallurgy, advanced materials, and research institutions. With a rated pressure of up to 60 tons (34MPa) and dual pressure capabilities reaching 300MPa and 500MPa for different mold sizes, this machine ensures reliable and uniform compaction of a wide variety of materials.

Built around a durable chromium-plated hydraulic cylinder with a diameter of 150mm, the KS-CIP-60J features a seamless structural design that minimizes oil leakage and maintenance needs, while increasing operational stability. Its intuitive dual-scale pressure gauge enables precise control over both forming pressure and compressive force, giving users full confidence during operation.

The maximum piston stroke of 50mm allows for a wide range of sample heights, and the press supports two main mold specifications:

Φ50×150mm (Max Pressure: 300MPa)

Φ35×150mm (Max Pressure: 500MPa)

Such versatility makes it ideal for applications in isostatic pressing of rods, tubes, blocks, and custom-shaped green bodies.

In terms of safety and user experience, the KS-CIP-60J is equipped with a transparent organic glass shield, providing protection while allowing full visibility of the pressing process. The machine’s working environment temperature range is set between 10°C to 40°C, ensuring optimal hydraulic fluid performance and consistent pressure output.

Its compact design (dimensions: 405×240×720mm) and moderate weight (180Kg) make it suitable for desktop or laboratory use without compromising functionality. Despite its small footprint, the unit provides the kind of power and reliability typically associated with larger industrial presses.

Key Features:

60T high-pressure capacity, dual mold compatibility for 300MPa and 500MPa operations

Seamless oil circuit structure, reducing the chance of hydraulic oil leakage

High-strength chromium cylinder, precision machined for durability and accuracy

Organic glass enclosure, safeguarding users while maintaining full visual access

Compact size, perfect for lab environments and small-scale production lines

Precision dual-scale gauge,monitors pressure and compressive strength in real time

Applications:

Powder compaction in ceramics, refractory materials, and magnetic materials

Green body forming for components requiring uniform density

Sample preparation in R&D labs, universities, and pilot production lines

Cold isostatic pressing (CIP) of medical, electronic, and aerospace parts

High-density compaction of metallic powders, graphite, and composite materials

Technical Parameters:

| Model | KS-CIP-60J |

| Pressure Range | 0–60T (0–34MPa) |

| Plunger Diameter | Chromium-plated cylinder Φ150mm (d) |

| Main Structure | Seamless connection to reduce oil leakage points |

| Pressure Gauge | Displays pressure and compressive strength |

| Maximum Plunger Stroke | 50mm (T) |

| Protective Cover | Organic glass |

| Operating Temperature | 10°C–40°C |

| Isostatic Pressure Capacity 1 | Φ50×150mm (M×N), 0–300MPa |

| Isostatic Pressure Capacity 2 | Φ35×150mm (M×N), 0–500MPa |

| Overall Dimensions | 405×240×720mm (L×W×H) |

| Machine Weight | 180Kg |