Product Description:

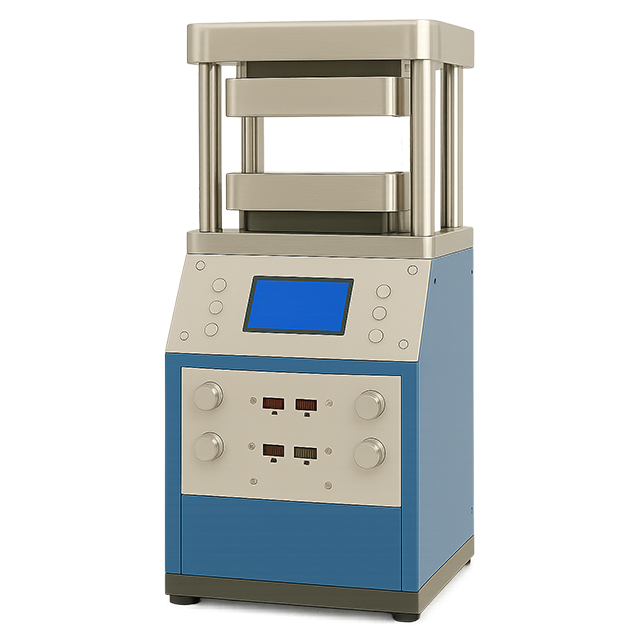

The KS-HP-600F Full-Automatic Hot Press Machine is an advanced thermal pressing solution designed for precise and efficient processing in a variety of research and industrial applications. With intelligent control systems, high accuracy heating elements, and customizable pressure and temperature programs, this unit offers a highly flexible platform for material testing, sample preparation, lamination, and composite material fabrication.

Constructed with premium-grade stainless steel and aluminum alloy, the KS-HP-600F ensures long-term durability and resistance to heat-induced deformation. The equipment features a fully automated workflow, including programmable pressurization, temperature ramping, pressure holding, and cooling phases, making it suitable for repetitive laboratory or production tasks with minimal operator intervention. The built-in touchscreen interface provides real-time process visualization and customizable parameter settings, enhancing usability and data reproducibility.

One of the machine's standout features is its dual temperature capability, with the option to reach up to 300°C or an extended 500°C range depending on configuration. This makes the KS-HP-600F ideal for applications that require variable thermal processing, such as thermosetting polymers, resin curing, PCB lamination, and sample densification in materials science. The temperature accuracy of ±0.1°C ensures consistent results, especially critical in processes where precise thermal control affects the mechanical or electrical properties of materials.

Technical Parameters:

| Model | KS-HP-600F |

| Pressure Range | 0–40.0 MPa |

| Pressing Process | Programmed pressurization – Programmed pressure holding – Timed pressure relief |

| Pressure Holding Time | 1 second ~ ∞ seconds |

| Mold Heating Temperature | Room temperature ~ 300.0°C |

| Temperature Holding Time | 1 second ~ ∞ seconds |

| Temperature Control Accuracy | ±0.1°C |

| Insulation Method | Imported insulation plate |

| Cooling Method | Rapid water cooling [Optional water chiller] |

| Mold Size | 400 × 400 mm (M × N) |

| Machine Dimensions | 500 × 550 × 620 mm (L × W × H) |

| Power Supply | 5500 W (220V/110V customizable) |

| Main Unit Weight | 480 Kg |