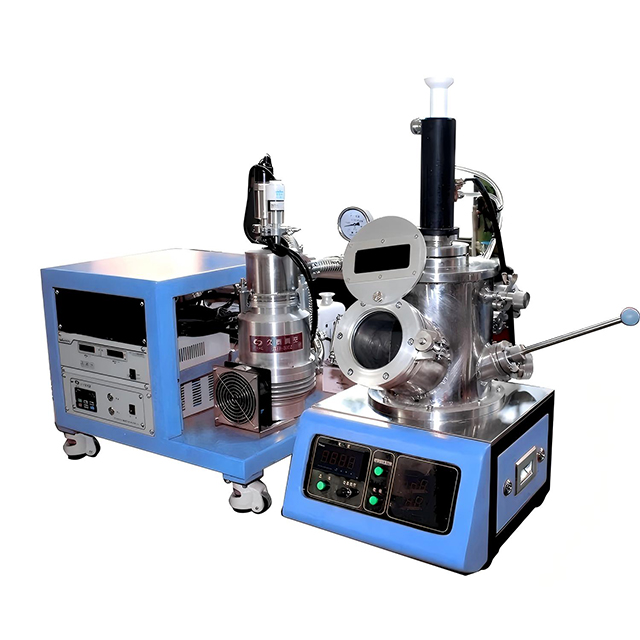

| Model | KS-VF-BG80 |

| Furnace Type | Crystal Growth Furnace with Bridgman / Directional Solidification Method |

| Application | Crystal growth using Bridgman / directional solidification method; routine growth of crystals up to Ø65 mm |

| Crystal Growth Environment | Vacuum up to 1500 °C; inert atmosphere up to 1600 °C |

| Crystal Growth Method | Vertical Bridgman method with precisely defined and controlled pulling speed |

| Maximum Crystal Diameter | ≤ Ø65 mm |

| Maximum Temperature (Short Term) | 1600 °C |

| Maximum Continuous Temperature | 1500 °C |

| Heating System | Resistance heating |

| Heating Rate | Up to 50 °C/min |

| Heating Zones | Three-zone furnace |

| Length of Each Heating Zone | 150 mm |

| Thermal Gradient | Stable axial thermal gradient |

| Temperature Measurement | Three C-type thermocouples |

| Additional Temperature Measurement | Probe thermocouple located next to the sample |

| Infrared Pyrometer | IR pyrometer integration supported |

| Temperature Control Method | PID control |

| Temperature Controller | High-precision Eurotherm 3504 PID controller |

| Temperature Control Program | 50-step programmable temperature profile |

| Temperature Control Accuracy | Independent zone control accuracy 0.1 °C |

| Axial Gradient Control | Programmable translation of temperature gradient along furnace length |

| Radial Uniformity Control | Radial division into four quadrants to eliminate radial non-uniformity |

| Critical Growth Zone Control | High-precision control within 1–2 inch axial heating zone |

| Furnace Tube Access | Swing-open furnace for quick access to furnace tube |

| Crucible Platform | Alumina platform Ø100 × 200 mm |

| Crucible Thermocouple | Thermocouple mounted at the bottom of the crucible |

| Sample Table | Automatic lifting sample table |

| Crucible Loading / Stroke | Automatic lifting system, 700 mm stroke |

| Furnace Vertical Travel | 500 mm |

| Furnace Moving Speed | 0.03 – 10 mm/h adjustable |

| Crystal Growth Rate | 0.3 – 10 mm/h adjustable |

| Atmosphere Control | Vacuum + inert gas |

| Working Gases | Argon (Ar) / Nitrogen (N₂) |

| Additional Gas Inlet | Additional gas inlet with valve and rotameter |

| Vacuum System (Standard) | Two-stage rotary vane pump + diffusion pump |

| Achievable Vacuum Level | Up to 10⁻³ mbar |

| Furnace Tube Material | High-purity alumina |

| Furnace Tube Size | Ø80 × 1700 mm |

| Chamber Structure | Stainless steel sealed flanges with water cooling |

| Cooling System | Closed-loop water chiller |

| Chiller Capacity | 10 L |

| Power Supply | 15 kW |

| Power Requirement | 220 V, 50 Hz |

| Equipment Dimensions (W×D×H) | 900 × 1000 × 3200 mm |

| Equipment Weight | Approx. 600 kg |

| Compatibility with Press Facility | Independent operation from VHP press system |

| Motion Control | Programmable movement with digital multi-step lifting control |

| Safety Protection | Over-temperature protection (shutdown on over-limit or thermocouple failure) |

| Power Failure Protection | Automatic resume from interruption point after power recovery |

| Sample Pulling Direction | Sample pulled downward into lower temperature zone |

| Pulling Mechanism | Sample and probe thermocouple fixed on bottom pulling device |

| Fast Movement Mode | Fast movement for loading and unloading |

| Growth Speed Control | User-defined pulling speed during crystal growth |

| Installation | Mounted on vibration isolation base |

| Alarm System | Remote alarm system supported |

| Documentation | Operation manual, maintenance manual, calibration certificate |

| Warranty | 1 year |

| Technical Support | Lifetime technical support |