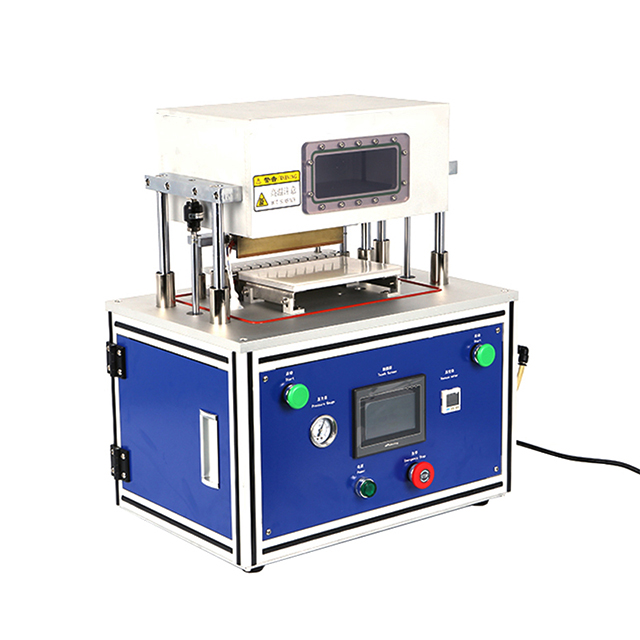

Product Description:

The KS-ISC Battery Internal Short

Circuit Tester is a precision-engineered safety testing system designed to

evaluate the internal short-circuit performance of lithium-ion and polymer

cells used in portable electronic devices, power tools, and electric vehicles.

It provides a controlled and repeatable environment to simulate real internal

short-circuit conditions inside a single battery cell, enabling engineers and

researchers to assess the cell’s safety behavior under extreme fault scenarios.

This equipment integrates mechanical,

electrical, and thermal control technologies to ensure reliable and accurate

test results. The system uses an advanced servo-driven loading mechanism

controlled by an industrial PLC to apply a precise and stable pressure on the

cell sample. The applied force, displacement, and duration are fully

programmable and continuously monitored through an intelligent touch-screen

interface. The entire process is automatically recorded, allowing detailed

analysis of the battery’s voltage drop, thermal response, and behavior during

short-circuit initiation and recovery.

The KS-ISC adopts a robust

explosion-proof test chamber to ensure operator safety even under severe

testing conditions. The chamber is constructed from reinforced stainless steel

with high-strength sealing and insulation materials, effectively containing the

energy released by cell rupture or combustion. An integrated pressure-relief

structure and forced exhaust pipeline safely discharge heat, smoke, and gases

to prevent secondary hazards. The viewing window, made from tempered and

bulletproof glass, allows clear observation of the test process, while an

internal explosion-proof LED lamp ensures visibility during operation.

Technical parameters:

| Item | Specification |

| Pressure head material | Stainless steel |

| Pressure head size | 10 mm × 10 mm square column |

| Position accuracy | ±0.2 mm |

| Pressing speed | 0.1 mm/s |

| Speed accuracy | ±5 % |

| Stroke range | 0 – 50 mm |

| Stroke accuracy | ±2 mm |

| Pressure range | 0 – 1000 N |

| Pressure accuracy | ±1 % ± 2 digits |

| Pressure resolution | 1 N |

| Voltage measurement range | 0 – 9999 mV |

| Voltage accuracy | ±1 % ± 2 digits |

| Voltage resolution | 1 mV |

| Temperature control range | 10 – 60 °C |

| Temperature accuracy | ±2 °C |

| Pressure holding time | 0 – 99 s |

| Time accuracy | ±1 s |

| Stepper motor torque | 8 kg·cm |

| Display & control | Touch screen or PC remote control |

| Power supply | AC 220 V ± 10 %, 50 Hz ± 2 Hz |

| Machine size (approx.) | 950 mm (L) × 1024 mm (D) × 1650 mm (H) |