The KS-BM-R68 single-station roller ball mill is a high-efficiency grinding and mixing system, engineered to meet the precise needs of modern laboratories and research facilities. With its compact structure, stable performance, and easy operation, it is an ideal solution for fine powder preparation, slurry blending, and advanced material processing.

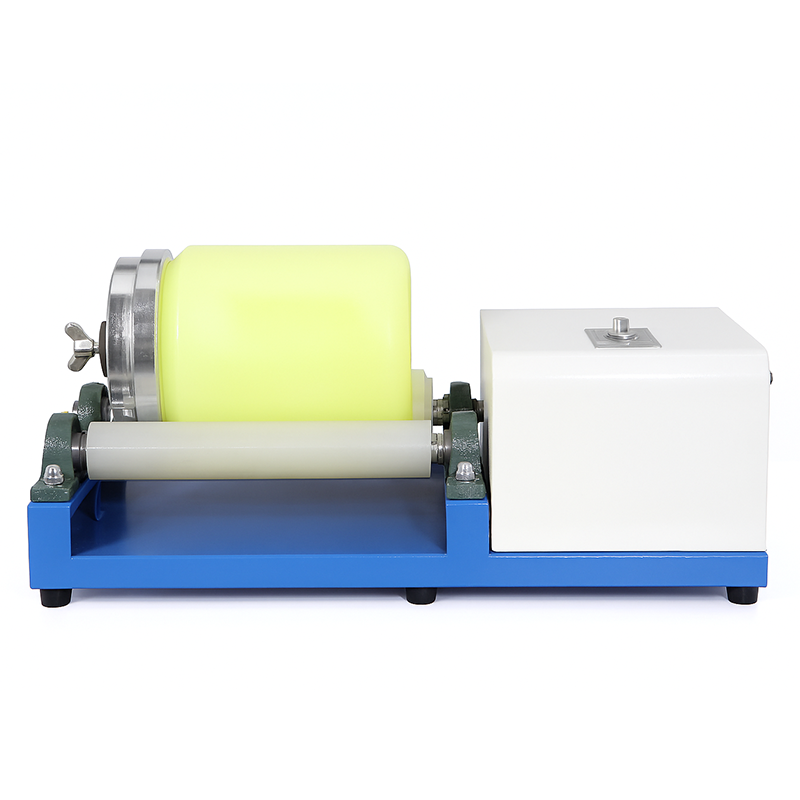

This machine is designed with a dual-roller structure, which drives a single grinding jar with smooth and uniform motion. The roller spacing is adjustable, allowing the user to accommodate a variety of jar sizes and materials. Its single-station layout makes it especially suited for focused experiments and small-batch production where precision and control are essential.

The KS-BM-R68 offers compatibility with different types of grinding jars, including PTFE jars for corrosive or sensitive substances and stainless steel jars for harder materials and high-impact grinding. These options provide flexibility for handling a wide range of chemical compositions and research applications.

Equipped with a user-friendly control panel, the system enables convenient speed adjustment and intuitive operation. This ensures that users can optimize milling conditions according to the specific requirements of their materials, whether for gentle mixing or intensive mechanical alloying.

Built with a strong steel frame and mounted on durable rollers, the machine offers long-term reliability, low noise output, and stable running. Its belt-driven transmission ensures smooth rotation and minimal vibration, contributing to precise and consistent milling results.

Safety features such as overload protection and controlled acceleration make it suitable for both novice and experienced users. Its clean design and small footprint also allow it to be easily integrated into any laboratory environment.

Whether used for ceramics, chemical compounds, metal powders, or composite materials, the KS-BM-R68 provides a flexible, efficient, and professional grinding solution. Its single-station format makes it a perfect choice for research labs looking for quality results in a compact and easy-to-use package.

Technical Parameters:

| Product Model | KS-BM-R68 |

| Mill Method | Roll milling type method |

| Pot and Step | Single pot |

| Roller Size | Φ 68 mm × 349 mm |

| Speed Controller | dail knob control |

| Speed Range | 10 to 1000 rpm |

| Power | 0.55KW |

| Jar | 1 EA |

| Roller | Rubber material |

| Body Material | Steel plate with powder coated finish |