- Home

-

Products

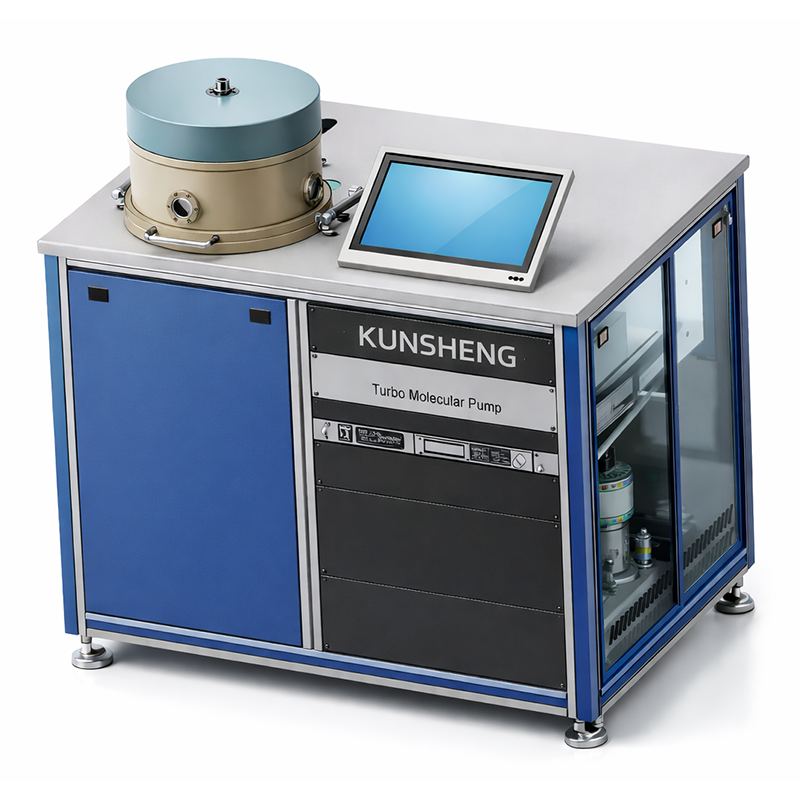

- PVD Coating Machine

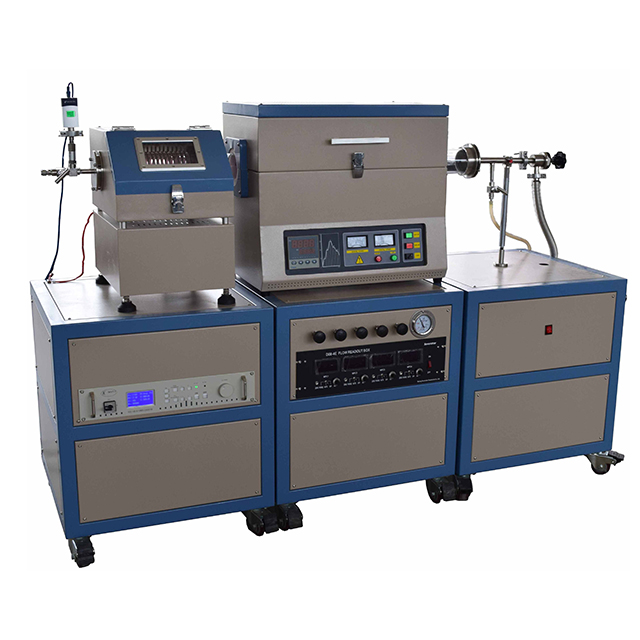

- CVD Coating Machine

- Battery R and D Equipment

- Spin Coater and Spray Pyrolysis

- Crystal Growth Furnace

- Vacuum Furnace

- Muffle Furnace and Tube Furnace

- Hydraulic Press Machine

- Vacuum Mixing Machine

- Grinding and Polishing Machine

- Cutting Saw

- Cleaning Machine

- Measurement & Analyzer Instrument

- About Us

- Technical Articles

- News

- Contact Us